Cutting costs: Why we’re all in it together

Whenever times get tough in the oil and gas industry it’s the big boys that take the blame but, more often than not, it’s the smaller firms, further down the supply chain, that are tasked with finding new and better ways of working.

Today, everyone is talking about cutting costs - 20% currently seems to be the magic number. In practice, this conversation involves some large offshore contractors turning to their suppliers and demanding solutions for efficiencies now.

Since tight job specifications often don’t allow room to seek more cost-effective solutions, the smaller players are typically left absorbing costs and waving off much of their profits. They do so in good faith; hoping that today’s sacrifices will lead to future gains - but once the market stabilises things go back to where they were and, ultimately, no one really wins.

Even though we’re one of the underdogs in this picture – tiny compared to the size of many of our clients – we are grown up enough to sit down with the major companies and engage in meaningful dialogue that benefits all parties.

We then support clients’ cost-reduction efforts by looking at their objectives and working together to jointly change the way things are done in order to achieve greater efficiencies.

Faced with the latest cost-cutting challenge laid down by the operators, we resolved to enter into a partnership with another like-minded firm, Magma Global, to develop an innovative solution which will help reduce costs of well intervention and extend field life.

A high-strength composite pipe product, m-pipe, has been designed by high performance pipeline manufacturer Magma to address ongoing challenges faced by oil and gas operators, including the need to maximise production from existing fields through more effective light well intervention.

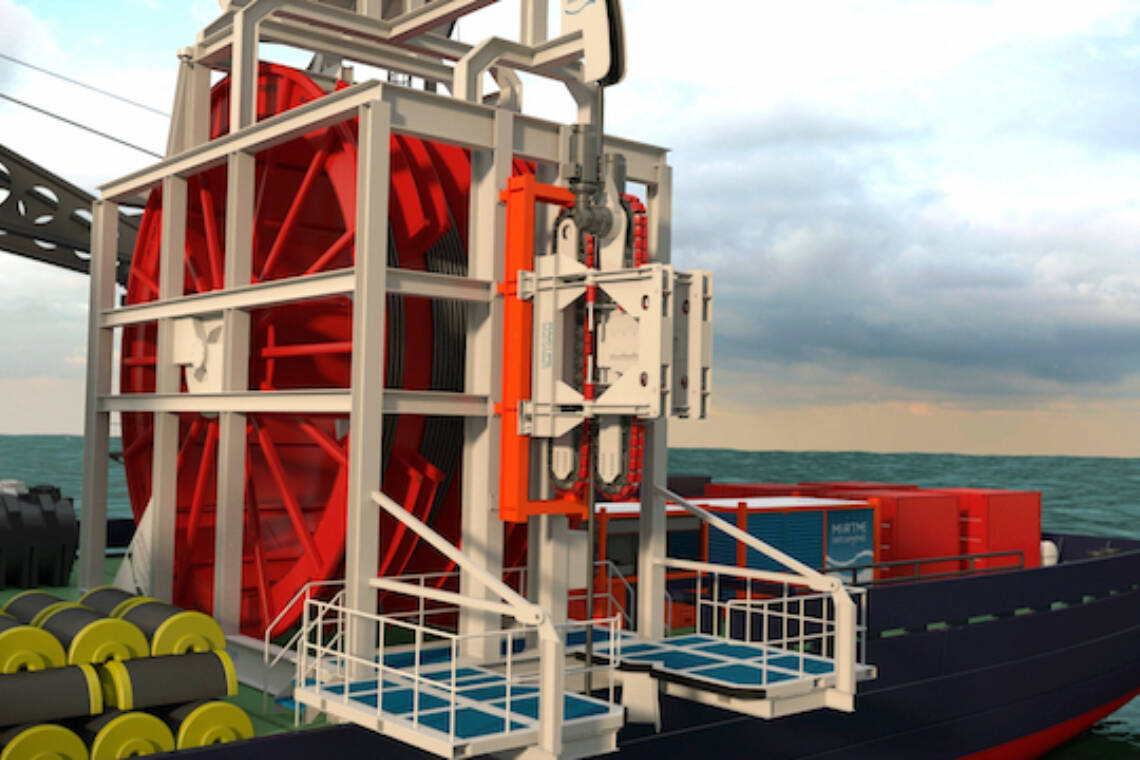

Our role in this expert partnership was to engineer a cost-effective and safe solution to optimise the use of the m-pipe®. To this end, we are delivering a complete back-deck package for the deployment and retrieval of m-pipe, including a bespoke compact vertical lay system (CVLS) with a built-in reel, to keep deployment vessel size down and minimise back-deck footprint.

Such is our belief in the innovation’s potential to increase safety, reliability and viability of intervention operations that we promote the m-pipe product as part of our company’s own presentations.

Over the past few months we’ve been invited by clients to share our proposal on cutting costs and how our technology can enhance their operations. We’ve reviewed previous jobs, looking at the processes and procedures, equipment components, as well as equipment utilisation post-delivery.

In each case we were able to identify significant cost reduction – provided the client was prepared to work with us on achieving these targets.

In our experience there’s a growing realisation of the important role played by the smaller firms in keeping costs down across the sector. The answer can no longer be to simply turn to the typical downturn tactic of squeezing the supply chain; instead, we need to strengthen the relationship between operators and suppliers and find ways to standardise procedures.

For too long, inefficient projects and spiralling budgets have been commonplace across the industry. One example we found recently was the large number of man hours and money being spent on re-certifying repeat procedures – costs that could have easily been avoided, helping reduce the overall cost of the project.

In our view, the solution to prevent these oversights from coming up time and again is greater involvement in the design of the equipment from all partners.

To put a reeler and tensioner together in a concise package for Magma’s m-pipe product posed several challenges, and the final design was the consequence of constructive communication between us, Magma and the end users to find the ideal solution for this unique product.

All of this demanded a significant time commitment from all parties, including repeated travel to Houston and Portsmouth by the Maritime Developments team, in order to perfect the design and fine-tune the solution to optimise the m-pipe as well as best satisfy customer requirements.

As a result, the integrated reeler and tensioner system can operate and store the pipe on a minimal footprint. And because of the light weight pipe, and therefore the low tension required to operate it, the structural design of the solution is much simpler than that designed for non-bonded and steel pipes.

The success of our approach with Magma, which has recently led to the details being finalised for the first reeler to go into production, will hopefully act as the catalyst for others to adopt a similarly collaborative approach.

Whether it’s the fall in the oil price that has made people more open to change, or we’ve simply been lucky enough to meet some like-minded innovators, it’s clear to us that there’s an appetite for greater collaboration in the industry at large.

And, speaking from experience, a joined-up approach to reducing costs can bring double the returns.

Mike Gaskin, commercial director

- April 2024MDL supports Saipem on Greece INGS

- January 2024Preparation is key to a long life subsea

- January 2024Forward thinking with Holland

- January 2024Ensuring peak performance for FPSO and platform owners in 2024

- December 2023Reducing the risk of cable failures