Cable Lay Tensioners

Electric or hydraulic systems

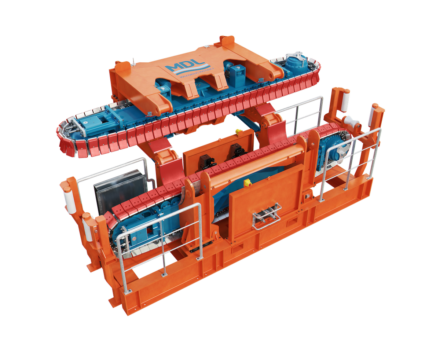

MDL tensioner range ensures safety and efficiency of cable handling operations - in a compact, road-transportable package.

Whether you are looking to convert your back deck into a cable-lay solution for offshore wind operations or to upgrade your onshore spoolbase with a user-friendly system, you will find your enabler in the MDL 2-track tensioner portfolio. Proven on global projects, including renewables scopes and shallow water installations of inter-array, fibre optic, subsea export and power cables.

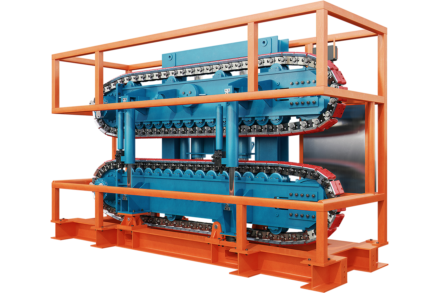

The range offers improved handling capability with adjustable grip and precise squeeze on the cable, automated through modern PLC software, developed by MDL engineers in-house.

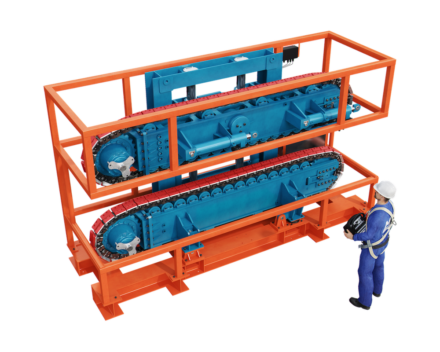

This ensures optimum handling of the product, but also carries safety improvements thanks to features mitigating loss of the cable in critical situations such as a power failure. Safety of the personnel is also ensured through remote controls.

To add to that, the systems' integrated and compact design results in quick mobilisation/demobilisation and reduced footprint. Depending on your requirements, you can choose between pivoting tracks for unparalleled opening for product recovery and abandonment; or in-line product entry when space is limited.

For our systems available for rent, look for our distinctive orange-and-blue range; or get in touch with our engineering team to design a system tailored to you.

Expertise

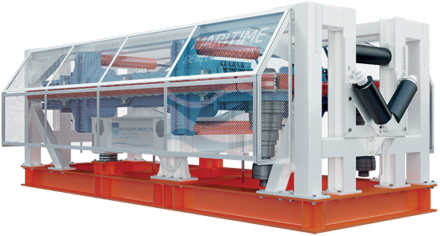

From our design and manufacturing bases, Maritime Developments delivers product handling equipment for global energy projects.

As well as tensioners, MDL delivers the full turnkey package of cable handling equipment including spoolers, under rollers, overboarding chutes, level winders, compensators and control systems.

Safety & Operational Excellence

Our range of cable lay tensioners is designed and manufactured to comply with PUWER / LOLER requirements and can be CE marked. The tensioner control system is designed for safe product handling with data logging as a standard feature. This ensures instant access to critical product lay information with the option to record the data which can be accessed during or post operation.

Design Considerations

- Type of vessel / operating conditions

- Deck mounting (horizontal / vertical / inclined)

- Maximum installation and recovery loads

- Product outer diameter

- Maximum allowable squeeze/meter on the product

- Co-efficient of friction of the product

- Optimum pad solution

- Operating product line speed

- Preferred drive option, hydraulic / electric