Industry Glossary

Ancillary Equipment

Supplementary or supporting equipment used alongside the enabling equipment to complement a lay or retrieval spread.

Asset Maintenance

Systematic and coordinated activities to optimise and manage assts and systems, their performance, risks and wear over their life cycles.

Back-deck Equipment

Equipment used for installation and recovery of flexibles, cables, umbilicals, and steel pipe products from a "back-deck", typically of a vessel or another floating platform.

Beach-pull, Shore-pull

Pipe lay or retrieval method connecting an offshore asset with an onshore facility, executed from the "beach" or in shallow waters close to the shore, e.g. from a barge.

Buoyancy (Modules)

A structure of low-mass material (usually foamed polymers) strapped or clamped to the exterior of flexible products, to reduce the submerged mass of the product.

Cables

Flexible products designed for electrical power supply and instrumentation on onshore or offshore assets.

Chute (Overboarding)

Equipment designed to route flexible product over the vessel side, stern or moonpool for subsea installation or retrieval. This aids in safe handling of the product by minimising damage due to friction or wear.

Coefficient of Friction (CoF)

The value which describes the ratio of the force of friction between two bodies and the force pressing them together. In flex lay operations for optimised and safe handling this value has to correlate between the specification of the product and the appropriate handling equipment (e.g. tensioner)

Coiled Tubing, MEG Lines

Continuous length of steel or composite tubing that is flexible enough to be wound on a large reel for transportation. It is a cost- and time-effective solution for well intervention operations where it can be inserted into the well tubing against its pressure and during operation.

Control System

A system of devices that manages, commands or regulates the behaviour of equipment or other systems to enable desired outcomes at any stage of the operation. May be integrated into the equipment or housed in a cabin.

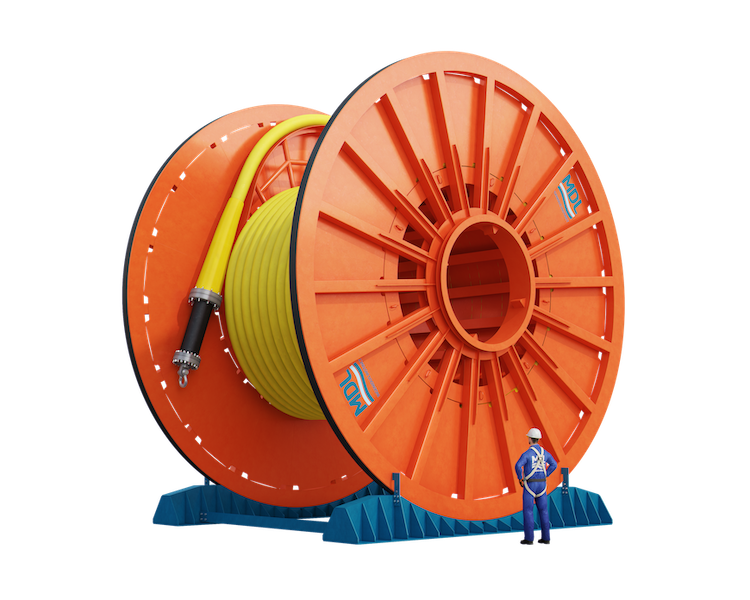

Cradles

The "seat" matching a reel's OD, enabling secure positioning of the reel on a vessel prior to deployment using a Reel Drive System or onshore for storage. MDL cradles are supplied with boltable inserts to accommodate various diameter reels, eliminating the requirement to weld / cut the reel cradles to / from the deck for multiple reels.

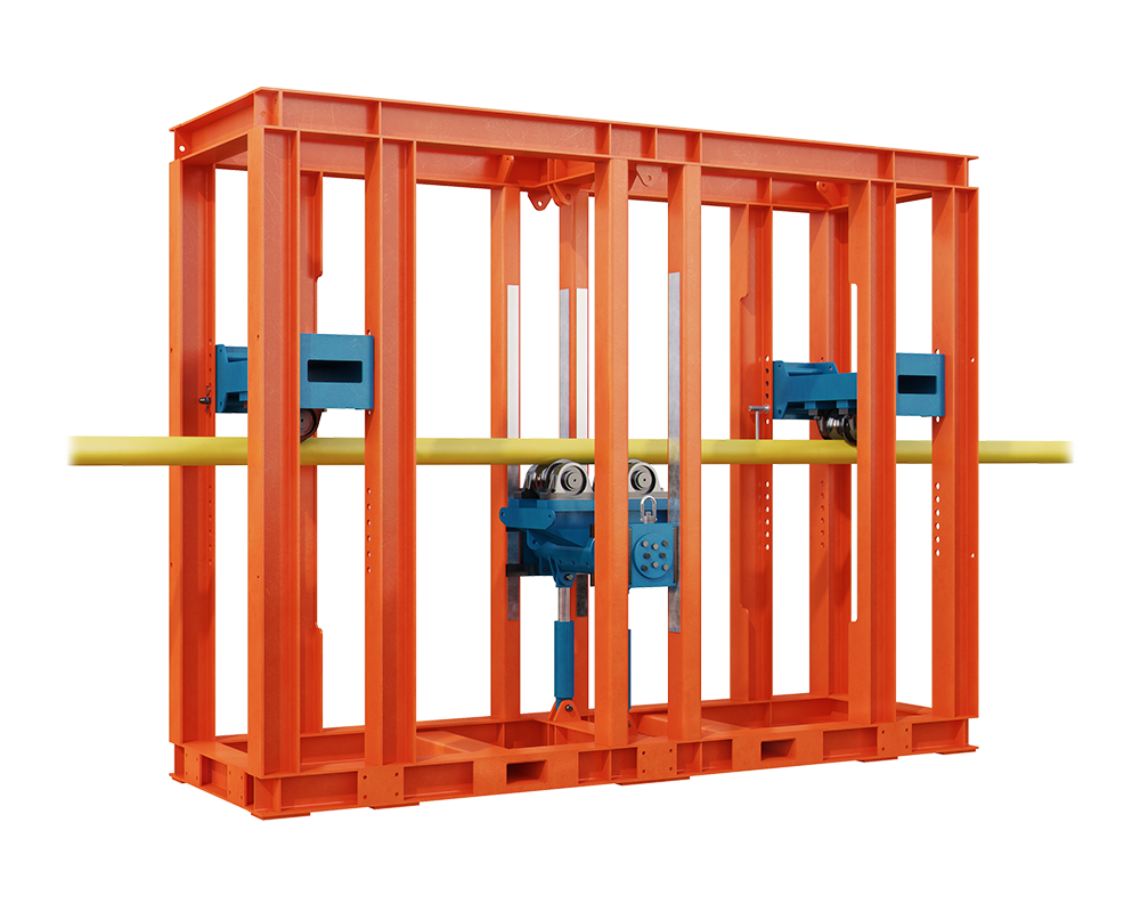

Deck Radius Controller (Deck Deflector)

Equipment used for directing flexible products, cables, and umbilicals in horizontal or vertical orientation. MDL deck radius controllers feature rollers to optimise product handling by minimising friction.

Decommissioning

The final stage of an energy project which involves deactivation and/or removal of production assets, with the surrounding area returned to its natural condition.

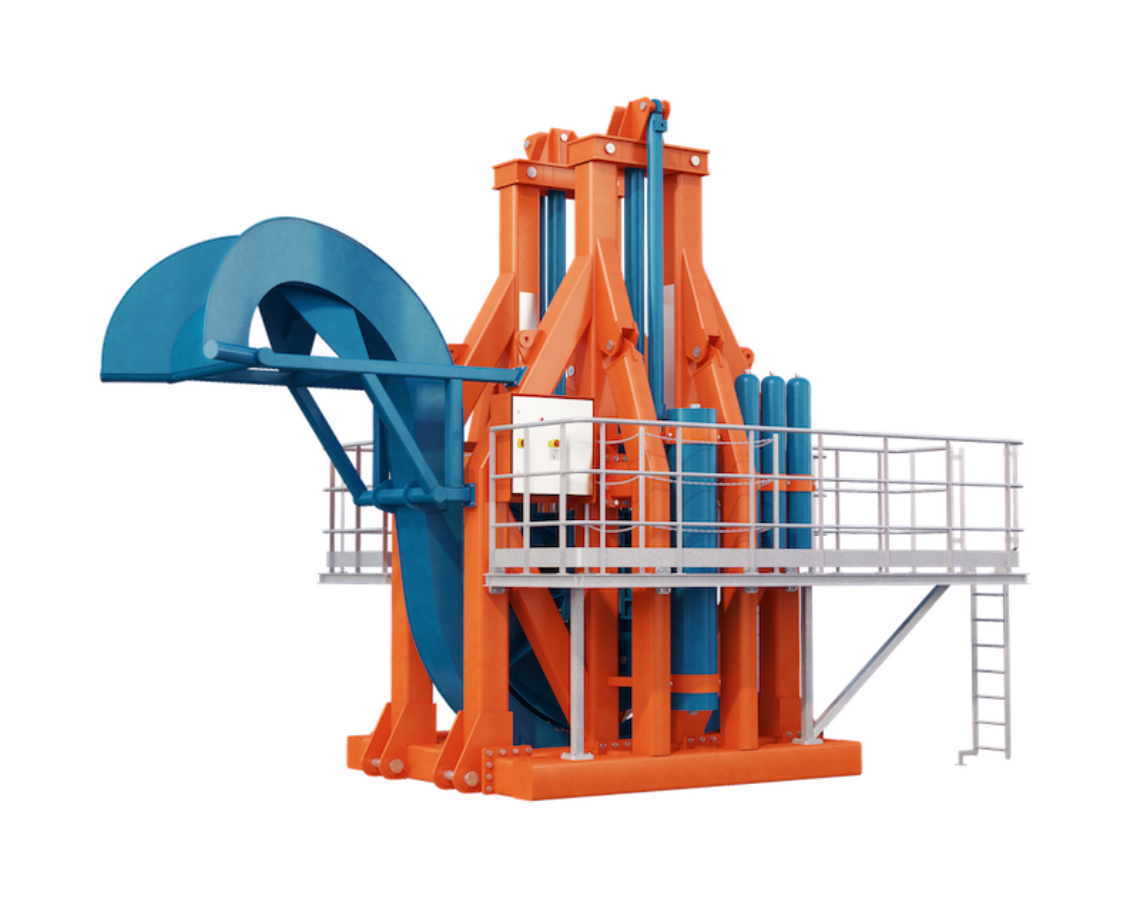

Deployment System

A system for the deployment, retrieval and storage of subsea umbilicals, risers, and flowlines (SURF) or composite pipe.

Electric Power Unit (EPU)

A powerpack for use with electrically-driven or electrically-operated equipment, such as tensioners and reel drive systems.

Engineering Consultancy

Provision of technical solutions and engineering advice, involving a discussion about the client's technical needs, followed by project management of the implementation of technical solutions in accordance with industry regulation.

Failsafe Grip System

A safety system unique to MDL tensioners on the rental market that eliminates single-point failure such as burst hoses and blackouts, thanks to the design of the hydraulic accumulators and their location on the tensioner's tracks.

FAT

Factory Acceptance Test -

FEA

Finite Element Analysis - computer-aided engineering tool used to analyse how a design will react under real-world conditions. The FEA can help design engineers reduce product development time and cost.

FEED

Front End Engineering Design - engineering activity following a Conceptual Design or Feasibility Study. At this Stage, before start of EPC (Engineering, Procurement, and Construction), various studies take place to understand technical issues and estimate rough investment cost.

Flexlay Equipment

A variety of equipment used for the handling of flexible pipelines, risers, and in-line structures.

Flowline

Flexible pipeline that connects a single wellhead to a manifold or process equipment. In a larger well field, multiple flowlines may connect individual wells to a manifold and gathering lines may transfer the flow from the manifold to a pre-process stage or to a transportation vessel.

FMECA

Failure Mode Effects and Criticality Analysis - a design study highlighting failure modes with relatively high probability and severity of consequences, allowing remedial effort to be directed where it will produce the greatest value.

FPSO

Floating Production Storage and Offloading system that receives fluids from a subsea reservoir through risers, which are then separated into crude oil, natural gas, water, and impurities within the topsides production facilities onboard.

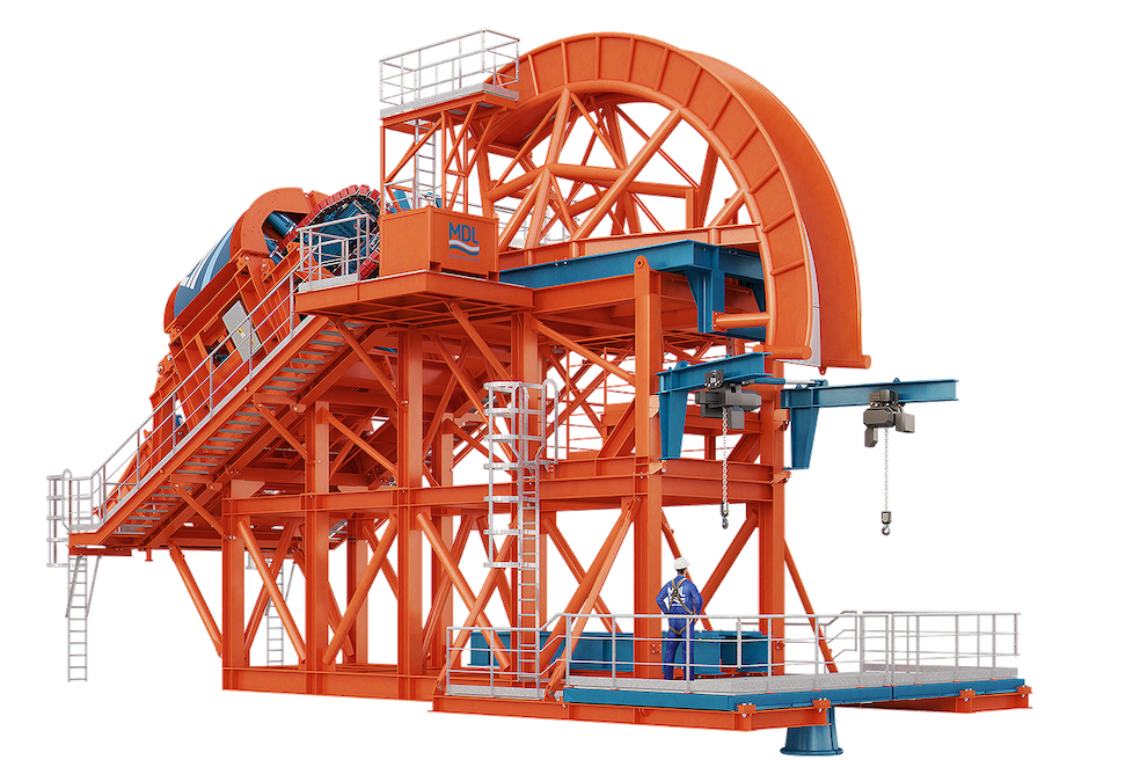

Horizontal Lay System (HLS)

A system that allows for the deployment and recovery of subsea, umbilicals, risers, and flowlines from an offshore facility, e.g. an Offshore Supply Vessel (OSV)

Hydraulic Power Unit (HPU)

A powerpack for use with hydraulically-driven equipment, such as tensioners and reel drive systems.

Inter-array Cables

At floating windfarms, inter-turbine cables are installed in single lengths from one turbine to its neighbour, forming a string (collection circuit) that feeds into a substation.

Line Pull, Line Tension

Pulling force of a lifting equipment (e.g. tensioner or winch) or the maximum permissible load of the wire tension.

LiveWire

An integrated system for inspection, maintenance and change-out of wire rope under constant tension.

Load Cell

A transducer which converts force into a measurable electrical output - this allows for monitoring the forces exerted on a product to ensure safe and optimised handling.

Moonpool Door

An opening in the floor or base of a platform (including vessels), giving access to the water below, allowing for lowering of tools and instruments into the sea as well as deployment or retrieval of subsea products.

Mooring Line

A line connecting a floating structure to an anchor on the sea floor. Commonly used materials are polyester, sheathed or unsheathed spiral strand (SSWR) and steel wire rope (IWRC).

OD

The outer diameter of a pipe - a measurement of the outside edges of the pipe passing through its centre. The outer diameter of a pipe, together with its wall thickness, are essential to inside diameter calculations.

Pipelay Equipment

Equipment facilitating the handling (pay-in or pay-out) of rigid and flexible pipelines as part of field start-up, tie-backs, IRM, and decommissioning scopes, covering every stage of a field's life.

Pipeline Replacement

Repair and/or maintenance scope on an existing pipeline due to internal/external damage, age or production issues. Typically involving the installation of a new pipeline segment adjacent to an existing pipeline, to allow the replacement works to proceed without stopping production through original pipeline - minimising environmental impacts.

Platform

An offshore platform or offshore drilling rig is a structure with onboard facilities for exploration, production, storage, and processing of hydrocarbons from offshore fields.

PLC

A programmable logic controller (PLC) regulates various automation and mechanical processes in offshore and onshore operations by maintaining direct connectivity with various field devices such as sensors, transmitters, and actuators.

Plug & Play (Design)

A fully-integrated design "ready to use". In back-deck technology, this design allows for quick mobilisation and demobilisation through centralised points for connecting the system to power supply (e.g. on a vessel)

Project Engineering

The process of planning and execution of engineering and technical projects - this includes management of assets, personnel, supply chain, budget, and schedule to deliver a successful project - covering newbuild, rental, repair & maintenance, and after-sales scopes.

Redundancy (in pipelay systems)

Redundancy is offered through additional or duplicate resources available to support the main system. It is a backup or reserve system that can step in if the primary system fails.

Reel

An asset for storage and/or installation of flexible or semi-flexible product, such as subsea umbilicals, risers, and flowlines (SURF), cables or polyester mooring rope. Can feature partitions and reinforcements specific for the product and intended application.

Reel Drive System

Drive systems used for spooling and unspooling of rigid and flexible pipe, umbilicals, risers, and other products stored on reels.

Renewables

Natural energy sources that are self-perpetuating and therefore unlimited, including wind, tidal, solar or biomass.

Riser

A specially constructed flexible product that delivers fluid between subsea equipment and surface bodies such as platforms, floating production storage and offloading vessels (FPS and FPSOs), and drill rigs.

SCADA

Supervisory Control And Data Acquisition - a centralised automation control system to monitor and control entire sites, e.g. all connected systems on a vessel.

Seafastening

Seafastening is the routine practice of fastening of equipment to the ship for transport or ahead of offshore operations.

Sheave Compensation

System used to improve operational safety and productivity offshore by offsetting dynamic sea-state conditions. It allows smooth running of a wire or rope by maintaining a constant tension setting, despite the vertical movement of the platform (e.g. a vessel) from which it is operating. Typically used for systems with wire rope such as winches and cranes.

Skidding System

A skidding system is comprised of a series of skid beams moved by hydraulic push-pull cylinders, traveling over a dedicated track.

Spoolbase

A spoolbase is a shore-based facility used to enable production of long lengths of pipe; allowing for welding of single or double joints of steel pipe into predetermined lengths for spooling onto a storage asset (e.g. reel or carousel) or directly onto an offshore installation vessel.

Steel Pipe

Non-flexible tubing for the transport of liquid or gas underground between locations, often for long distances allowed for by the product's durability.

SURF

Subsea Umbilicals, Risers and Flowlines - subsea production and surface systems.

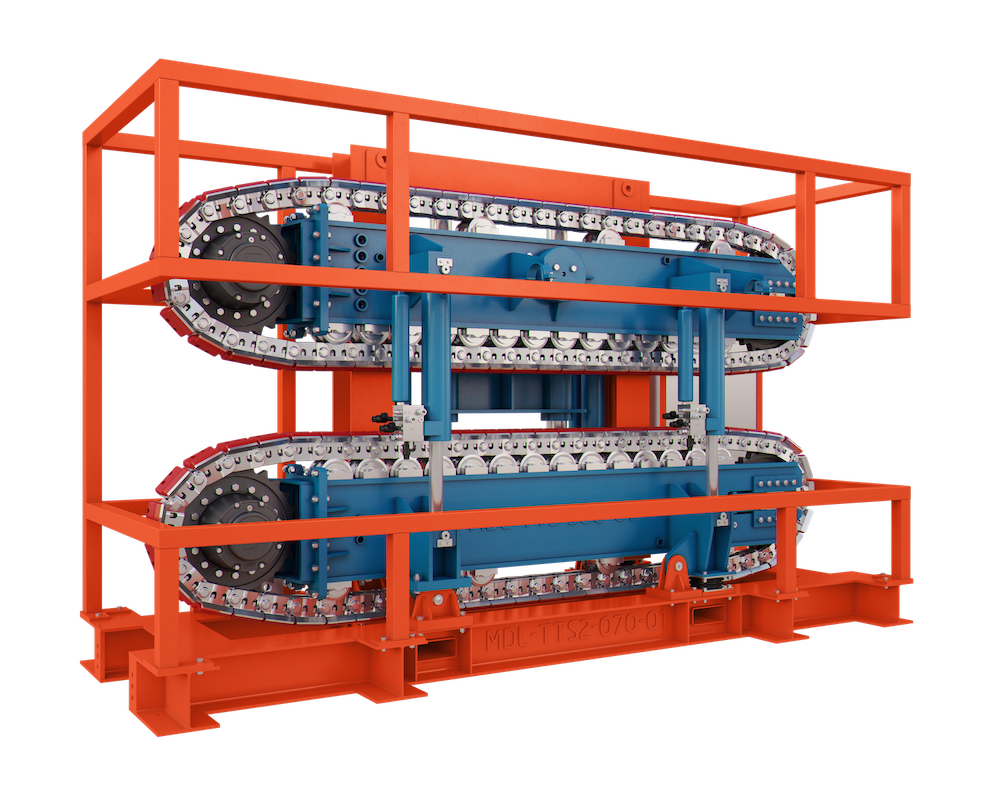

Tensioner

A system for the installation or recovery of flexibles, cables, umbilicals and steel pipe products. MDL tensioners' tracks are fitted with ‘V’ shaped pads and operate by gripping the product between the opposing track carriages with failsafe hydraulic cylinders.

Testbed

Platform for conducting rigorous testing of the equipment used in onshore and offshore operations, replicating on-project conditions.

Tie-back

A connection between a new oil and gas discovery and an existing production facility.

Transpooling

The process of spooling a flexible product from one storage system to another (such as a reel or a carousel), as part of an inspection, installation, recovery or replacement scope.

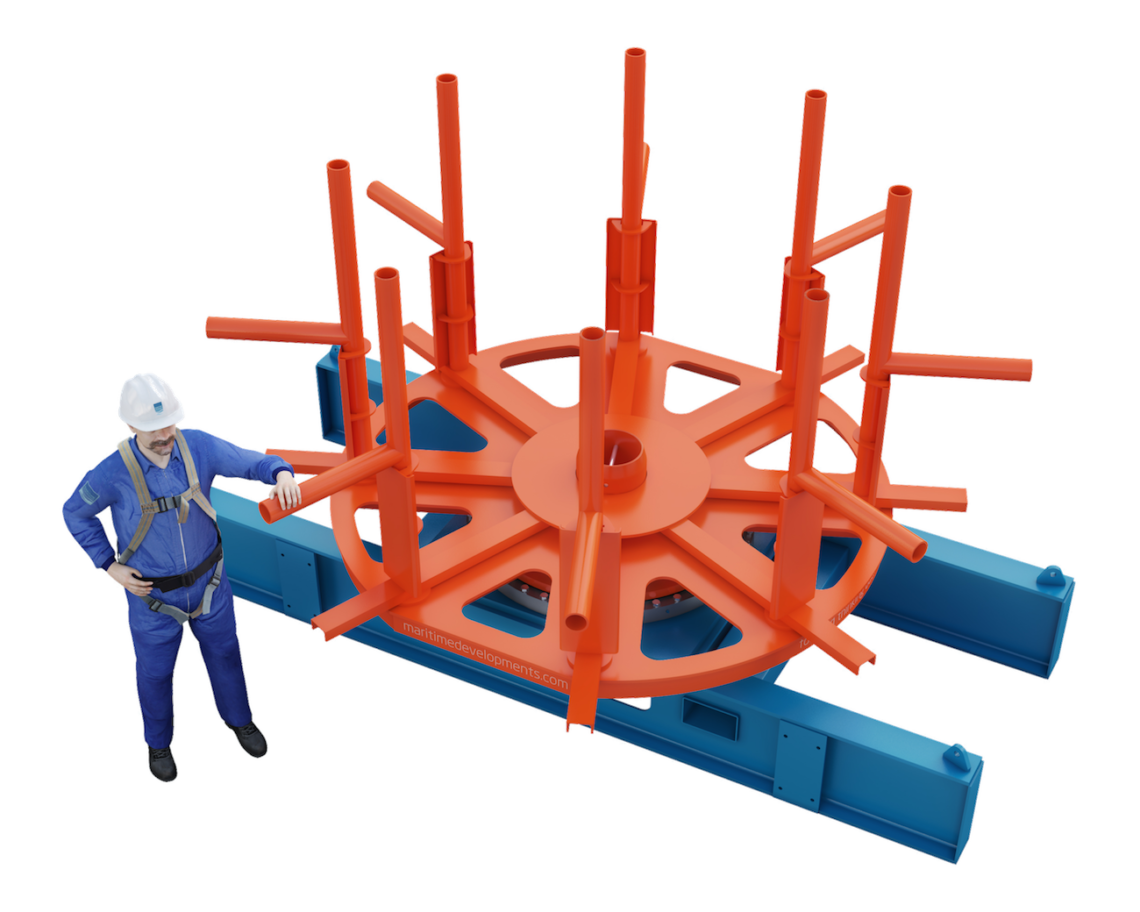

Turntable

Rotating powered equipment for the installation or recovery of umbilicals and flying leads.

Umbilical

Flexible product for connecting subsea equipment to platforms or floating production units and enabling the control and operation of the production well from the surface.

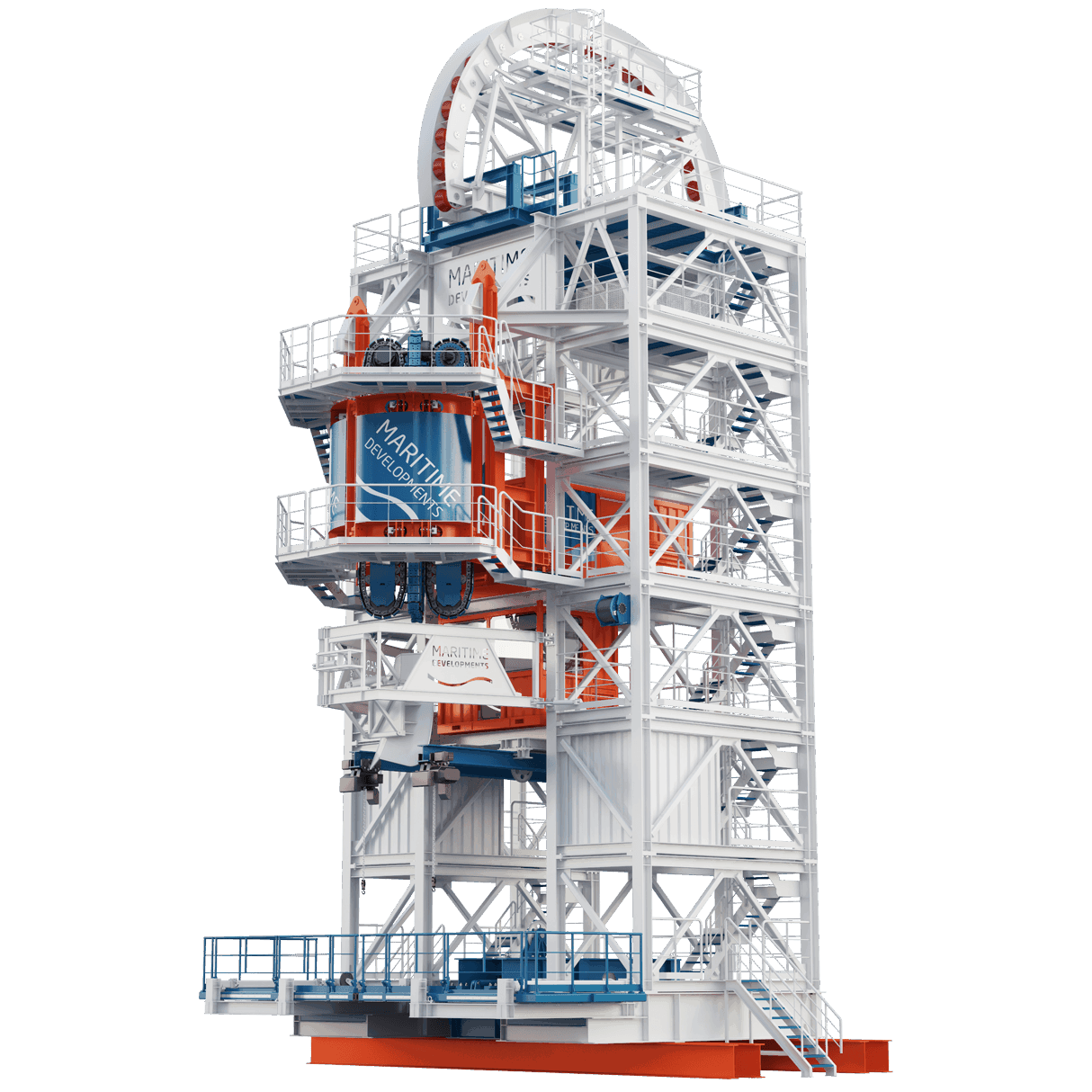

Vertical Lay System

Portable vertical lay system for the deployment and recovery of subsea umbilicals, risers, and flowlines (SURF). The system allows for safe and efficient vertical deployment of product from on-deck reel drive systems and carousels, over the side or through the moonpool of a vessel.

Vessel of Opportunity

Any available/accessible vessel which can be converted into a cable, mooring, SURF or pipe lay/retrieval solution when enabled with mission-specific equipment.

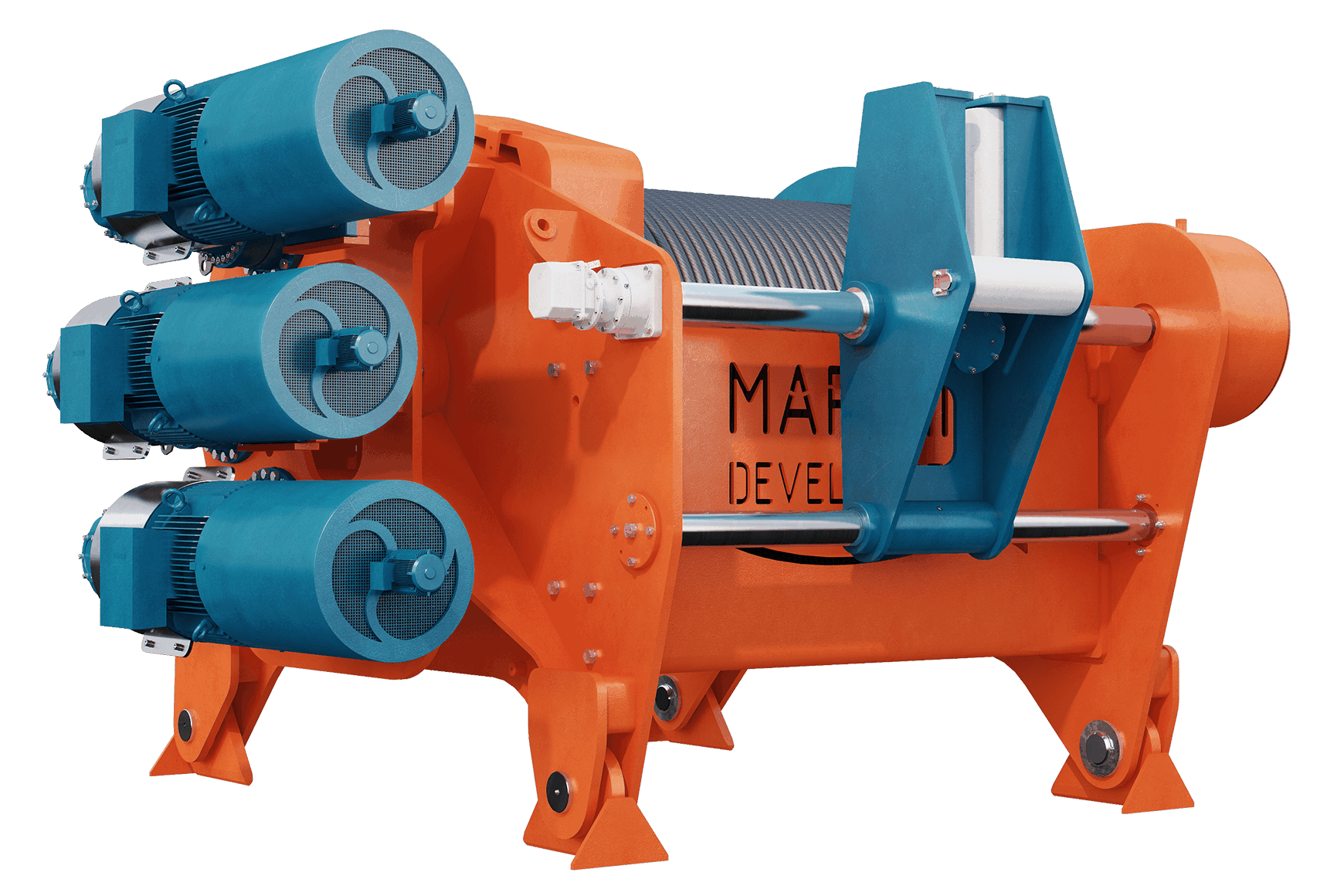

Winch

A hauling or lifting device consisting of a rope or chain winding round a horizontal rotating drum, turned typically by a hydraulic or an electric motor.

Walk About Box (WAB)

A wireless remote controller allowing the on-deck personnel to operate the equipment from the most optimal location and from a safe distance. MDL's state-of-the-art control system allows for full functions to be controlled and features remote dialup for service and maintenance.