Transpooling Case Study

Mooring line replacement

In with the new - out with the old

Challenge

This offshore contractor was looking to replace the mooring lines on their South America-based FPSO. The polyester rope - manufactured in Europe - had to be first transpooled onto installation reels before shipment overseas.

MDL Solution

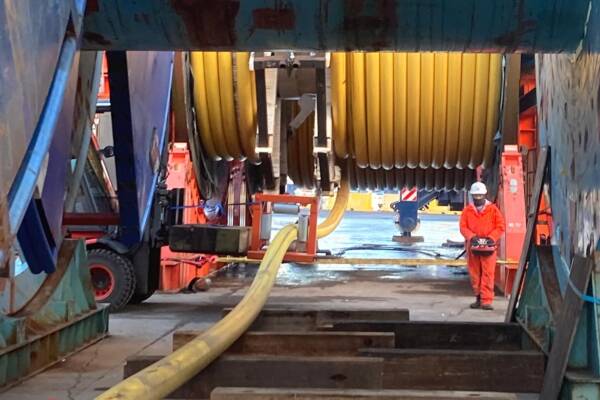

Well experienced in these operations and in handling polyester rope, MDL provided project engineering services throughout the operation, which included the development of a transpooling procedure, reel packing arrangement drawings, task plans, HAZID/HAZOP and provision of experienced MDL operators for onsite execution. The operation was performed at MDL’s quayside location in Peterhead using the MDL Generation 3 Reel Drive System and a Generation 1 RDS to transpool 2x 2000m polyester ropes from two 5m storage reels onto two high-capacity MDL 8.6m installation reels. The specialist installation reels were specially selected for the expected back tension on deployment of the rope offshore, as they offer 30Te at the flange rim radius.

Outcomes

Following the transpooling, MDL reels with the polyester product were mobilised onto a cargo vessel, ahead of shipping across the Atlantic for the mooring line replacement on the FPSO. The old rope was spooled back onto MDL reels for disposal onshore. Once the reels were back in Peterhead, MDL Generation 3 RDS was used for the controlled unspooling of the product, which was cut into road-transportable pieces using a shear cutter. By providing a comprehensive service for each stage of the polyester rope's replacement, MDL delivered efficiencies through single-sourcing, streamlined project engineering and technology focused on reducing non-productive time.