Transpooling Case Study

Transpooling MEG injection lines

Two clients, 28 reels and One Team MDL

Challenge

Two clients: Ocean Installer and DeepOcean were looking to transpool MEG injection lines in preparation for their respective upcoming projects in the North Sea - both for the same Norwegian operator. In total 28 reels of coiled tubing were to be transpooled onto 7 installation reels.

MDL Solution

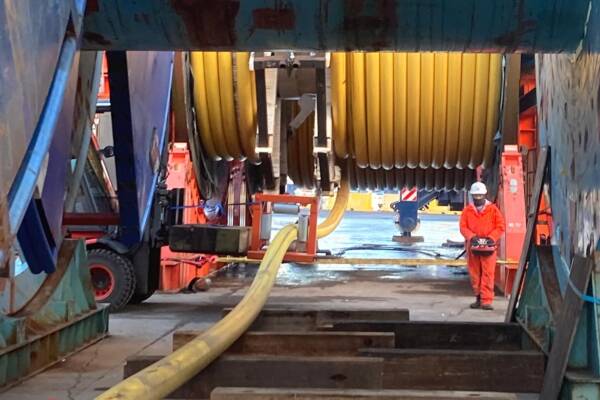

MDL project managed and engineered the complete operation, which included: project engineering, scheduling, transpooling procedures, task plans, mob/demob procedures, straightener testing, reeling verifications, back tension for spooling calculations, straightening analysis, general equipment list, data sheets and general arrangements, transpooling equipment setup/layout, lift plans, HAZID/HAZOP and marine personnel for onsite execution. The MDL transpooling spread consisted of MDL Second-generation Reel Drive System for handling the installation reels, 150Te reel drive system for handling the transportation reels, two 2-track pipelay tensioners to ensure controlled constant tension to protect the product, a pipe straightener, deck deflectors, roller assemblies and winches.

Outcomes

By having the complete capabilities in-house, MDL was able to streamline engineering, management and execution of two projects, and as such delivered a true value-adding package for two clients during a single mission, against the backdrop of the ongoing pandemic and the associated travel and personnel restrictions. The project was also a great example of collaboration for cost efficiencies: despite the products being destined for two different fields, the two clients worked together to deliver a single transpooling campaign. Effectively that meant a 100% cost saving on project engineering, mobilisation costs, equipment and personnel rates, compared to carrying out two separate transpooling campaigns – adding true value to the end client.