Transpooling Case Study

Turnkey jumper handling package

From transpooling and inspection to offshore installation

Challenge

In preparation for a jumper replacement in a Norwegian North Sea field, TechnipFMC had to transpool the product, to allow modifications to the reel and ensure correct orientation of the end termination.

MDL Solution

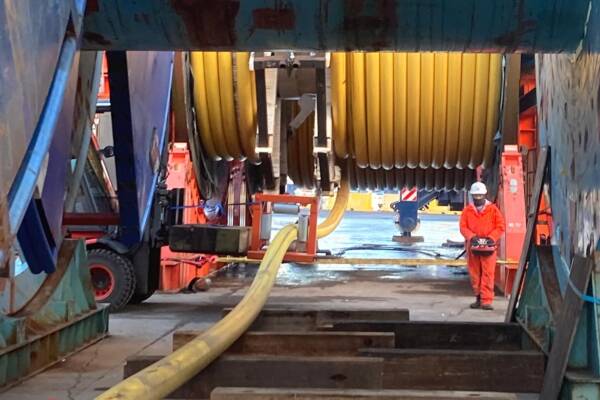

MDL provided project engineering services throughout the operation, which included development of transpooling and packing procedures, storyboard drawings, task plans, provision of transpooling equipment, HAZID/HAZOP and provision of experienced MDL technicians for onsite execution. An MDL Second-generation Reel Drive System was used for the handling of the client's 8.6m reel. Additionally, the MDL Operations team assisted with the inspection and SIT of the product while spooled into its expected seabed configuration to verify orientation of the end termination.

Outcomes

The project followed shortly from another transpooling campaign elsewhere in Norway using the same MDL RDS. This ensured the system was freshly proven for the job, but also minimised transit costs for the client and any transport concerns due to COVID. There were further benefits of using the system: MDL had built the RDS around the reel in-situ, which eliminated the requirement for a crane hire for lifting the reel, and is also the preferred route when handling product with end terminations of this size which affect reel and product centre of gravity. Following the transpooling, the same MDL RDS was deployed alongside the MDL TTS-2/140 Series Tensioner on board the TechnipFMC vessel to carry out offshore installation of the jumper.