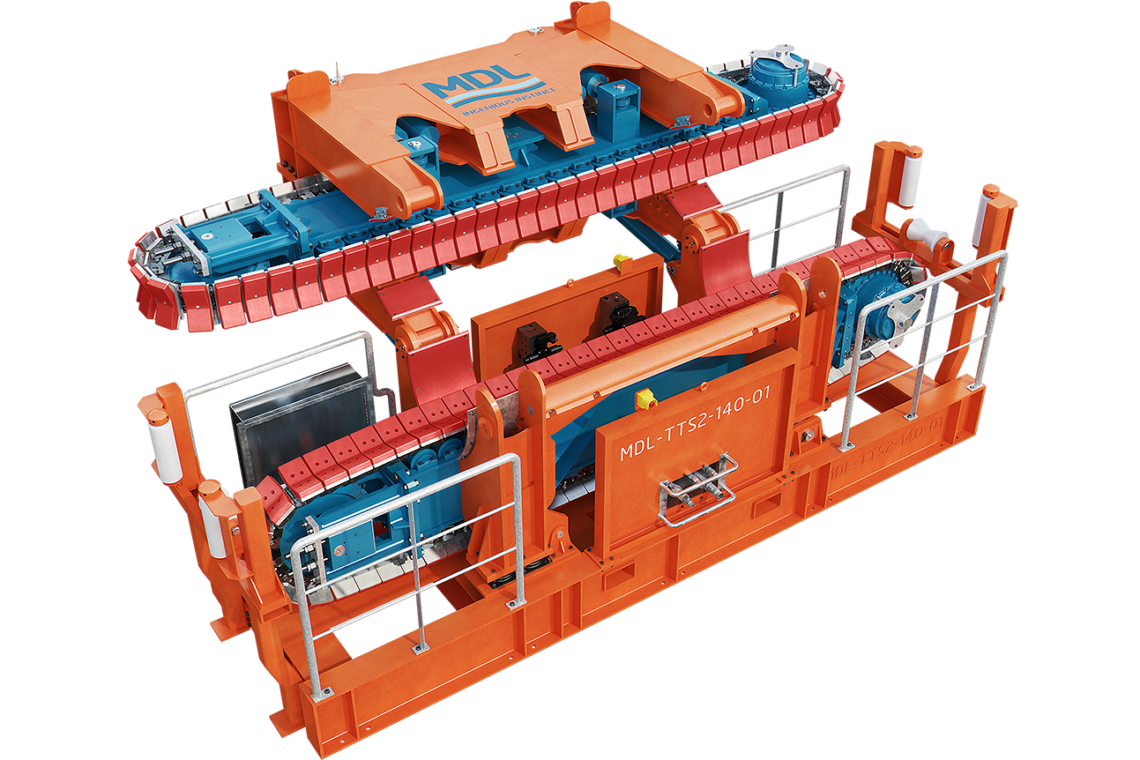

TTS-2/140 Series Tensioner

2-track system

The MDL TTS-2/140 Series Tensioner is a 25Te line pull, 2-track system for the installation or recovery of flexibles, cables, umbilicals and steel pipe products.

The tracks are fitted with 'V' shaped pads and operate by gripping the product between the opposing track carriages with hydraulic cylinders.

The system is compact in size with the top track rotating out of the firing line to provide a large area for accepting the product.

Properties

Dimensions (closed)

5.5m x 1.6m x 3.8m (LxBxH)

Dimensions (open)

5.5m x 3.2m x 3.8m (LxBxH)

Weight - 16.5Te

Specification

Operational mode

2 track mode

Track contact length

3.35m

Maximum grip

140Te/track

Max squeeze/m

41.8Te/m

Max pull force (idler end)

25Te at 0.09 CoF

19.6Te at 0.07 CoF

Product speed (installation)

0 - 1,200m/hr (at 60Hz supply)

Product speed (recovery)

0 - 1,000m/hr (at 60Hz supply)

Tension control

10 - 100%

Product Capacity

Product range

0 – 620mm OD (may require additional track pad sets)

Maximum track opening

Unlimited

Ancillary Equipment

Electro-hydraulic powerpack

3.0m x 2.4m x 2.5m (LxBxH)

Weight – 6.5Te

Control van with spares container

3.0m x 2.4m x 2.5m (LxBxH)

Weight - 4.0Te

Hose & Cable Package

20m set from powerpack to tensioner unit

20m power cable from powerpack to control van

20m power cable from powerpack to vessel

Lifting Equipment

1 x lifting rigging set for the tensioner

1 x lifting rigging set for all ancillary equipment

Assumed Conditions

Humidity

Up to 100%

Atmosphere

Marine/high salinity

Power Requirements

Supply 1 (main system)

3 Phase, 440V, 60Hz, 200amp supply at full load

Additional Information

Tracks driven by hydraulic motor/brake/gearbox drive assembly to deploy or retrieve the product.

The two track carriages are mounted in the main structural frame. This is connected to the mounting frame with low shear mounts and load cell pins for accurate product load information.

Both tracks open hydraulically to load/unload product and close to grip the product when operational.

The track carriages are mounted on kingpins so that they can pivot if the outside product diameter tapers.

Thanks to this design, the tensioner can be top loaded or line loaded with the product.

Supplied with a dedicated electro – hydraulic power pack, which drives the track motors and operates the track cylinders.

Remote operator’s control panel can be fitted within an existing control room or dedicated cabin.

Quick connect/release package of interconnecting cables and hoses completes the basic system.

Standard and custom track pads can be supplied to suit client product requirements.

Unit is road transportable or can be shipped in 40ft at rack containers. Facility for data logging and remote interrogation subject to set-up and bandwidth on-board vessel.

Note: For purchasing the unit can be offered with electric drives.