Transpooling Case Study

Flowline deployment: from UK to India

Combining MDL AME and equipment support

Challenge

Hindustan Oil Exploration Company (HOEC) had purchased two 6” static flowlines, stored in Port of Blyth, England. They required the product to be transpooled onto installation reels for deployment offshore India, in time for their operations - only one month away.

MDL Solution

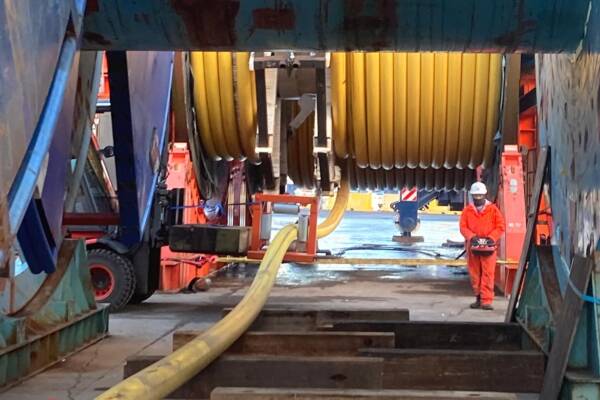

MDL provided engineering support, on-site project management and the supply of equipment and services to carry out testing and transpooling of the product. An MDL spread combined of a Second-generation and Third-generation Reel Drive Systems was used to move over 4,200m of product from 2 storage reels onto 2 MDL 9.2m installation reels. MDL also provided the design of the site layout, a transpooling method statement, design of partitions on the installation reels and lifting drawings for the fully-loaded reels.

Outcomes

Awarded to MDL on 23rd December and commencing during the festive period, this was a fast-track project, with the mobilisations, testing, transpooling, reel load out and site demobilisation completed within 5 weeks – all against the backdrop of the pandemic. The installation reels and one of MDL reel drive systems were already stored in Blyth, which minimised mobilisation costs for the client; and thanks to our equipment being road-transportable, the remaining equipment efficiently transited from MDL's Peterhead base.