Flex Lay Myths: Redundant reel drives

Let's explore the topic of reel handling systems - and why that's not the same as reel "drive" systems.

Offshore "flex lay" operations play a pivotal role throughout different stages of a field's lifecycle.

The term refers to the installation of flexible pipelines or flowlines on the seabed to connect a subsea structure with another facility, which may be floating offshore or located on land. Typically, this is to either transport fluids or to enable remote control of the subsea structure over a period of time.

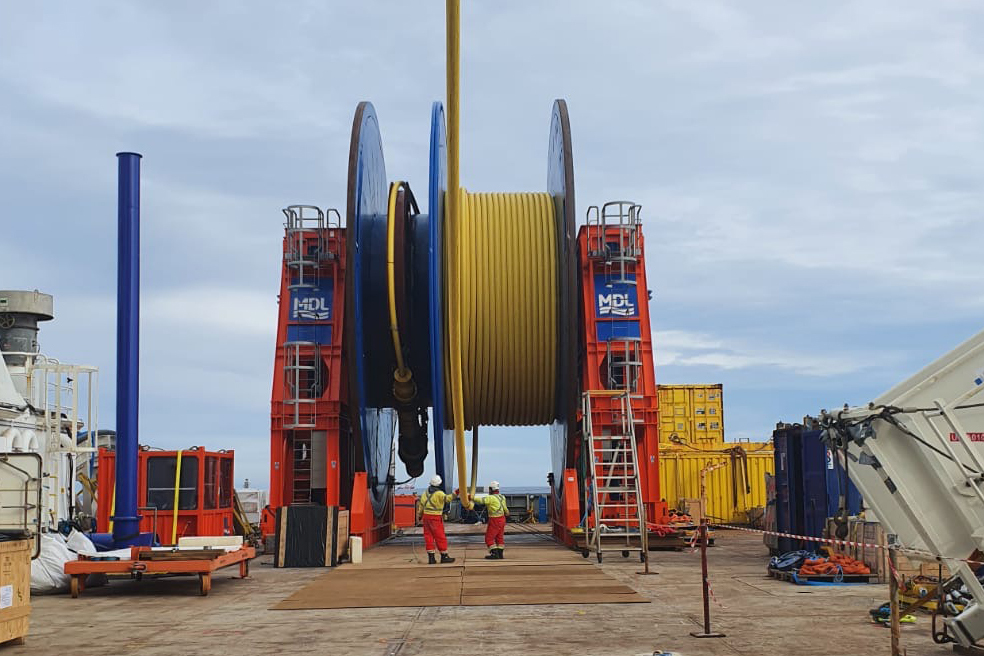

The eponymous flexible nature of these products means they can be stored in coils; and depending on their overall length, those coils can be packed into large carousels or more portable reels.

For the latter, the common deployment tool is - unsurprisingly - a “reel drive system "; but - beware - this is not a catch-all term.

If you have been involved in planning a flex-lay project, you will have heard of Under Rollers or Spoolers; and while they can certainly rotate a reel, they do not match the capability of a Reel Drive System (RDS).

If you ever had to choose a solution for handling reels, you may have wondered how the more advanced RDS can truly benefit an operation that - on paper - a less complex system can do more cheaply?

In our Flex-lay Myths series we aim to debunk the common misconceptions surrounding the flexible handling market. In this issue, we shed light on the differentiators among reel drive systems and explore their versatile applications beyond SURF, or flex lay - and help you see how choosing the cheapest option by day rate, is hardly ever the best value to ensure your overall project success…

Debunking the myths

Myth 1: Reel drive systems are complex and difficult to operate.

Fact: Disregard any preconceived notions you may have heard from flex-lay veterans about the equipment. Today's RDS are thoughtfully designed with user-friendliness in mind. They boast advanced automation features, intuitive controls, and user-friendly interfaces, making operation straightforward.

These RDS systems operate on PLC systems and seamlessly integrate with other back-deck equipment, ensuring a smooth and safe operation by allowing different elements of the lay spread to communicate with each other. Moreover, you have the option to choose between electro-hydraulic RDS and fully electric ones, which significantly impact the controls' responsiveness.

Thanks to the intuitive design, experienced personnel can quickly adapt to these systems, and the incorporation of built-in failsafe technology and all-stop ESD integration effectively minimises the risks stemming from human error.

Furthermore, maintenance is a breeze with modern RDS as they are engineered for reliability, resulting in minimal downtime and enhanced operational efficiency.

Myth 2: Reel drive systems are expensive and not cost-effective for smaller projects.

Fact: While Modern RDSs do require a higher initial investment compared to less specialised reel handling systems, their long-term benefits and cost savings far surpass the upfront expenses.

The efficient installation process enabled by RDS significantly reduces project timelines and minimises the need for offshore personnel, thanks to their intuitive controls and automation.

Moreover, these advanced features optimise the handling of the product and improve installation accuracy, resulting in reduced risks of repeat pay-outs/pay-ins and the associated costs. Whether it's a large-scale offshore SURF project, a smaller subsea installation, or beach-pulls, RDSs prove to be remarkably cost-effective, enhancing the overall project budget substantially.

Myth 3: Reel drive systems have limited adaptability to different project requirements.

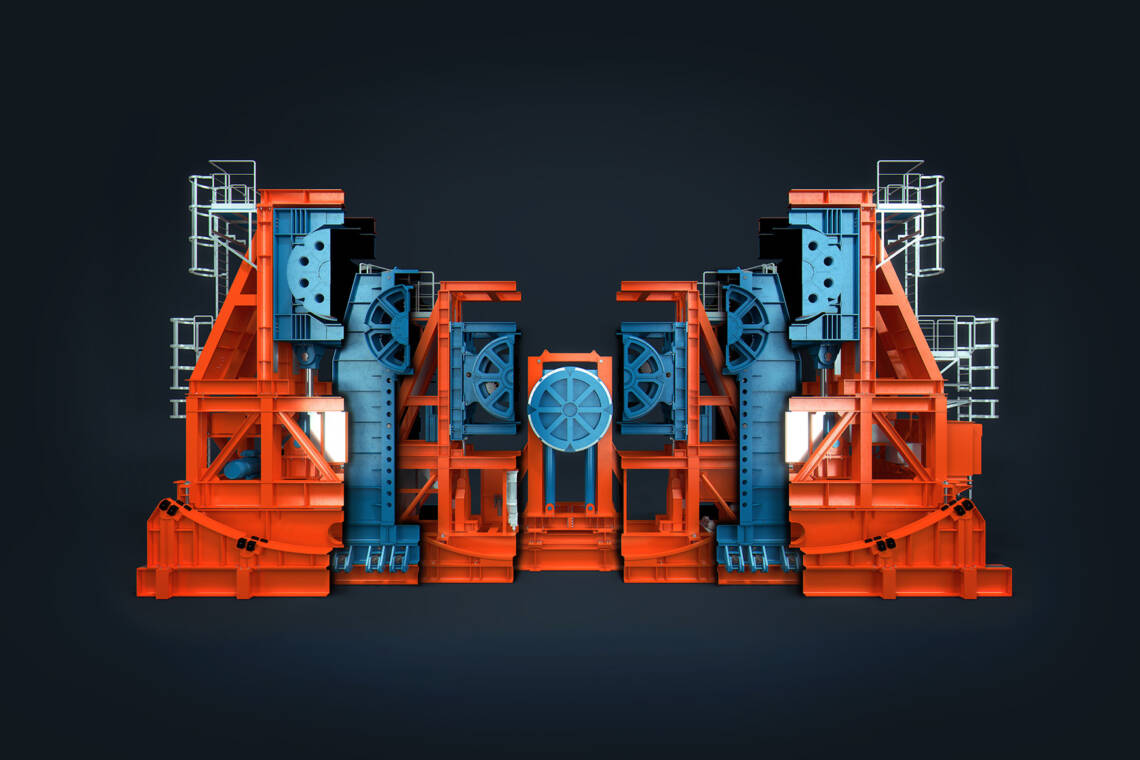

Fact: If you envision RDS as bulky towers and occupying extensive space with a large track system, it's time to reconsider. Our flexlay equipment fleet boasts three generations of reel drive systems, each equipped with a diverse set of advantageous features and optimised for specific reel types and sizes. These variations stand as a testament to the adaptability of RDS, allowing for customisation to meet specific project requirements.

Furthermore, our RDS effortlessly integrate with other subsea installation equipment, including tensioners and carousels, to create a streamlined and efficient installation spread, tailored precisely to the project's scope. The versatility of RDS opens the door to countless applications and combinations, making them a highly versatile solution for various projects.

Myth 4: Reel drive systems are only suitable for offshore SURF installations.

Fact: While earlier we discussed "flex lay" in the context of O&G operations, the application spectrum of RDS extends far beyond that narrow scope.

RDS are incredibly versatile, finding utility in a wide range of subsea operations, including SURF (subsea umbilicals, risers, and flow lines), cables, polyester mooring ropes, and flexible product installation, transpooling, recovery, or decommissioning scopes. This adaptability makes RDS a valuable asset not only in the oil and gas industry but also in the renewable energy sector, interconnector installations, and other construction scopes requiring precise handling of flexible products within set parameters to ensure optimal deployment and safe execution.

Consider the application of RDS in mooring rope deployment. The precision control over torque and speed offered by reel drive systems results in consistent and controlled deployment, preventing overstretching or damage to the ropes. This ability to maintain optimal tension significantly enhances the integrity and reliability of the mooring system.

With such versatility and precision, RDS prove to be indispensable tools in a wide array of subsea operations, supporting efficient, safe, and reliable execution across diverse industries and projects.

We trust we made a clear case for RDS’ differentiation from other reel driving systems, but the distinction doesn’t end there - because not all RDS have been made equal. Click through to part 2 to read why...

- April 2024MDL supports Saipem on Greece INGS

- January 2024Preparation is key to a long life subsea

- January 2024Forward thinking with Holland

- January 2024Ensuring peak performance for FPSO and platform owners in 2024

- December 2023Reducing the risk of cable failures