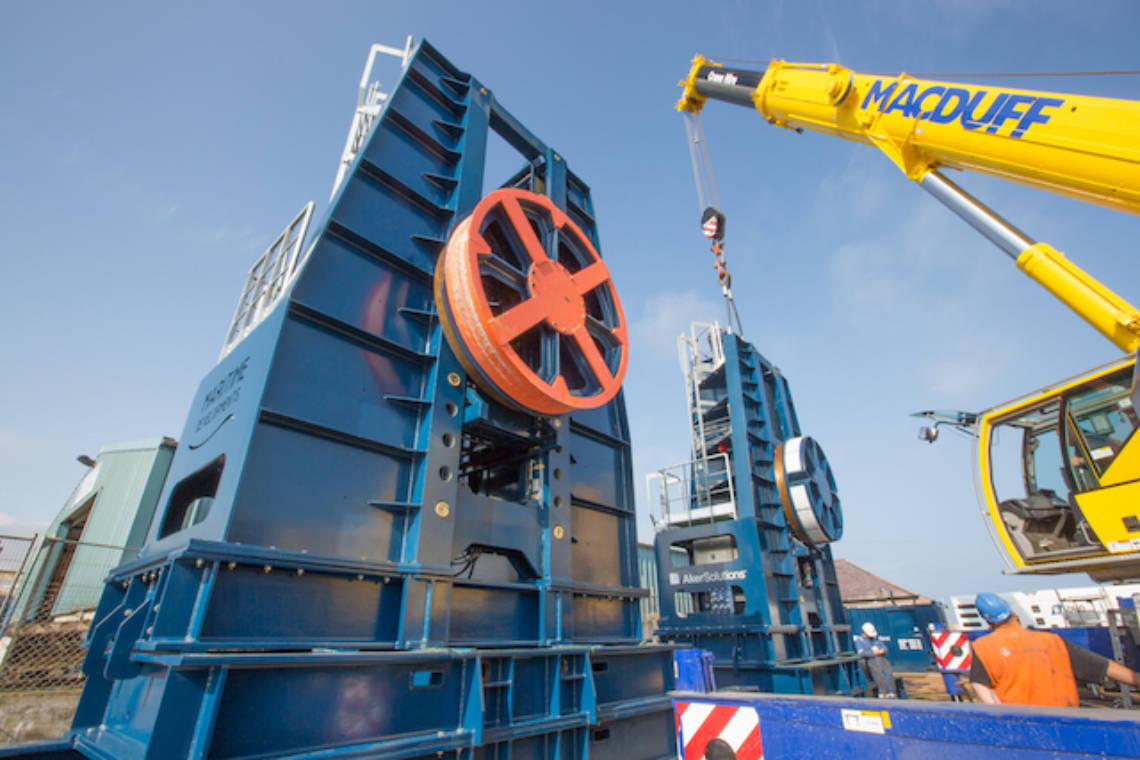

500Te Reel Drive System

The MRDS-500-150 Series Reel Drive System is a modular reel drive for the installation or recovery of flexibles, cables, umbilicals, wire rope or steel pipe products.

Properties

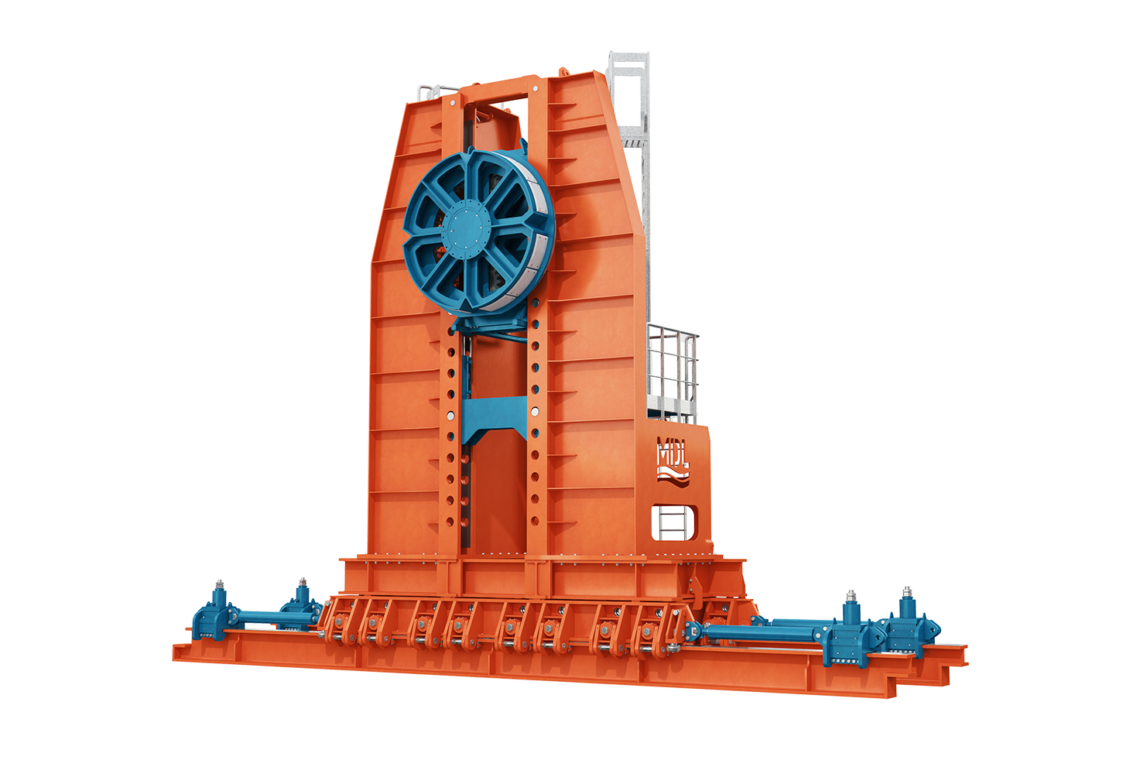

Reel drive tower (each)

5.55m* x 3.2m x 8.6m (LxBxH) assembled

Weight 80Te (*tower base)

12.0m track section (each)

12.0m x 2.25m x 0.53m (LxBxH) weight – 8.5Te

7.0m track section (each)

7.3m x 2.25m x 0.53m (LxBxH) weight – 5.1Te

5.0m track section (each)

4.96m x 2.25m x 0.53m (LxBxH) weight – 3.5Te

Electro-hydraulic powerpack (HPU)

3.5m x 2.4m x 2.5m (LxBxH) weight – 6.5Te

Control van

5.0m x 2.4m x 2.5m (LxBxH) weight – 4.0Te

Spares container

3.0m x 2.3m x 2.4m (LxBxH) weight – 6.0Te

Performance

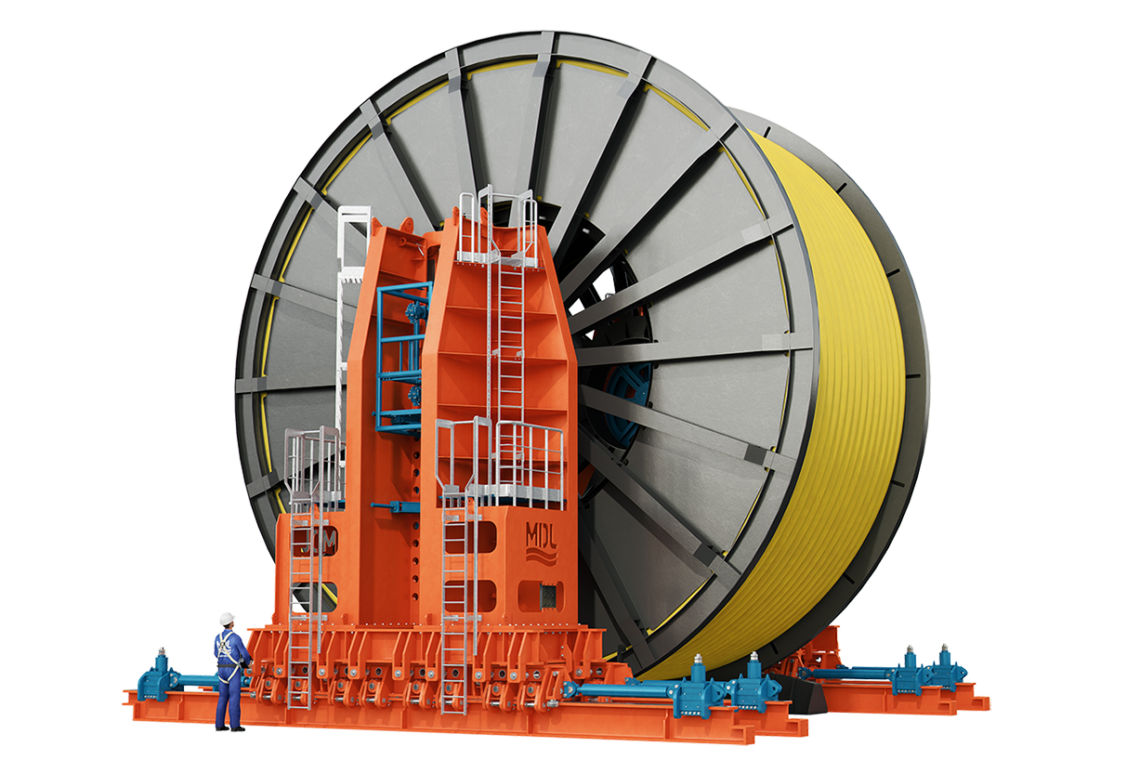

Maximum reel weight

500Te

Maximum reel diameter

12.2m

Minimum reel diameter

Unlimited (with packers below reel)

Maximum torque

150Te/m

Max hub rotation speed

1.0 rev/min at 75Te/m (high speed/low torque)

Max hub rotation speed

0.5 rev/min at 150Te/m (low speed/high torque)

Maximum line pull on 12.2m reel

21Te at outer flange

Assumed Conditions

Humidity

Up to 100%

Atmosphere

Marine/high salinity

Design Appraisal

Design appraised in accordance with LR Code for Lifting Appliances in a Marine Environment 2013, Chapter 4, Section 4

Lifting Equipment

All items supplied with dedicated rigging rated for onshore lifts

Hose & Cable Package

20m set from HPU to reel drive tower 1

20m control cable from control van to HPU

Wireless walk about box supplied as option for control

Power Requirements

3 Phase, 440V, 60Hz, 250amp supply

Additional Information

The system is suitable for reel diameters 12.2m and below with a combined reel + product weight of 500Te.

- Hubs driven by hydraulic motor/brake/gearbox drive assemblies with failsafe closed brakes.

- Track system can be supplied so the towers can move between reels.

- The unit has failsafe closed walking clamps.

- Automated clamping system to reduce downtime when moving between reels

- The raising and lowering of reels is automated to reduce working at height requirements.

- ESD system for local and remote use.

- The unit is supplied with dedicated electro-hydraulic powerpack.

- Ability to interface with other pipelay equipment such as tensioners.

- Road transportable or can be shipped by container vessel in components.

- Supplied with quick connect/disconnect hoses.