Flex Lay Myths: Tensioner capabilities

Selecting tensioners based on their line pull capacity alone may be a costly mistake - we explain why in this myth-busting blog.

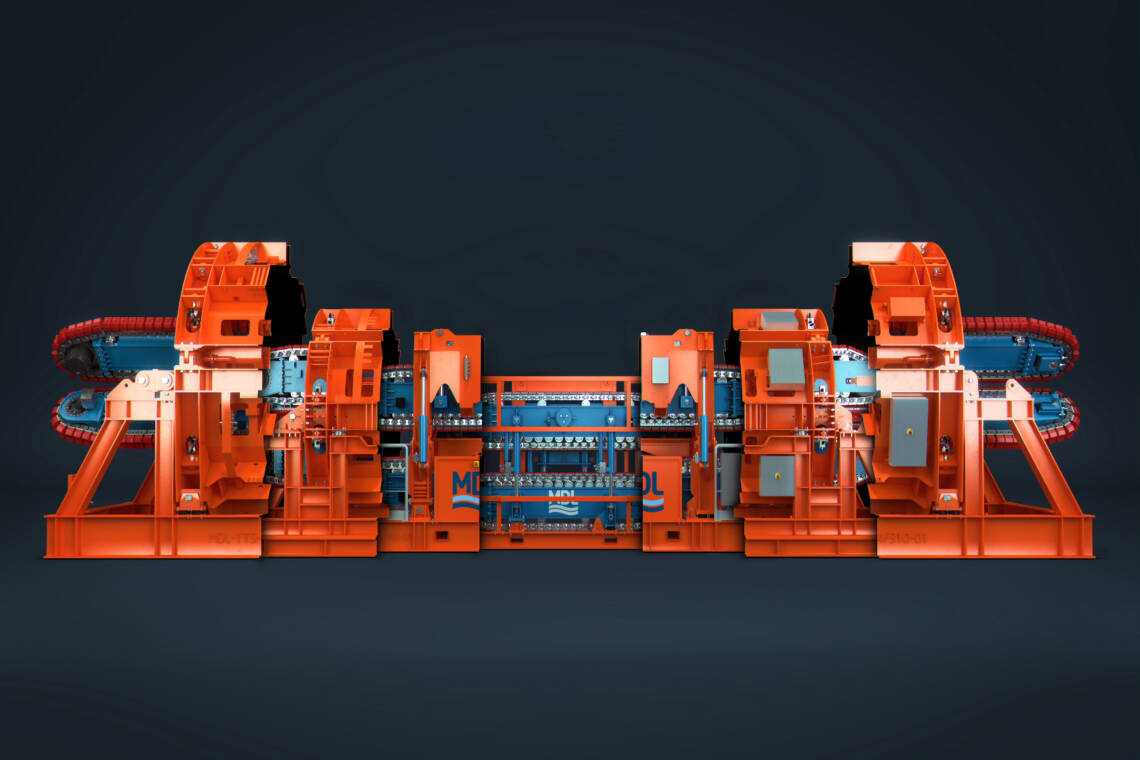

In our previous Flex Lay Myths blog we explored the misconceptions surrounding Reel Drive Systems; and while the MDL range leads the flexlay market in their capabilities as stand-alone units, there will be many operations that will require the use of a tensioner system.

Let’s take a deep dive into why that is – and why looking at a system’s line pull capacity in isolation may prove to be a costly fallacy.

Tensioner Applications

In the context of flex-lay operations, tensioner systems are used for controlled deployment or retrieval of cables, SURF, steel wire rope or pipes, referred to collectively as “products”. Some of the key reasons for using these systems include:

- Tension control - to ensure safe and controlled installation or retrieval of the products in line with the operational parameters

- Precise monitoring of operational parameters such as speed, tension and compression

- Precise placement – keeping the product in the firing line during onshore or offshore operations and deployed in the desired location subsea or on deck

All of the above have the overarching objective of maximising the safety of the operation and preserving integrity of the handled product, regardless of where it is in its lifecycle.

Tensioner systems come in various designs and configurations, depending on the specific requirements of the flex-lay operation and the characteristics of the products being installed. They can be surface-based or integrated into other lay structures, such as vertical or horizontal lay systems, where they become the enabling force for product handling.

Choosing a tensioner system for your job will therefore come down to a few factors, which need to be given equal attention: from the project environment – for offshore this includes the water depth and sea-state conditions and the back deck from which the system will operate – to the product’s specifications.

Today's market offers a pool of tensioner systems to choose from - but not all are made the same.

Debunking the myths

Myth 1: All lay tensioner systems are suitable for flex lay

Fact: Flex-lay tensioners are engineered to handle the unique challenges associated with installing flexible lines. Precise tension control, constant monitoring capabilities and built-in safety systems ensure the integrity of the installation process. MDL systems specifically are equipped with advanced features such as fails safe grip systems that ensure each grip cylinder is locked independently in the event of a pressure loss.

Using a generic tensioner not designed for flex-lay can result in compromised safety, decreased efficiency, and potential damage to the product or the equipment. At MDL we pride ourselves on having made flex-lay our focus back in 1999 and sticking to it ever since.

Myth 2: Tensioners are a one-size-fits-all solution

Fact: It is a misconception to believe that all flex-lay projects can be accomplished with a standard tensioner system design. The truth is that each project has its own unique requirements, ranging from water depth and pipe diameter to environmental conditions. Flex-lay tensioners should be customisable and adaptable to these diverse demands.

The use of modular tensioner systems allows operators to tailor the equipment to specific project needs, ensuring optimal performance and efficient installation. Thankfully, MDL systems tick all of the boxes on customisation and modularity!

Myth 3: Tensioners are high-risk systems / have limited safety features

Fact: Industry old timers may think that tensioner systems lack comprehensive safety features, making them potentially hazardous to personnel and product. However, tensioner technology has moved on significantly. Modern flex-lay tensioners incorporate multiple safety mechanisms, such as overload protection, emergency stop functions, and real-time monitoring systems. These features ensure that the system operates within safe limits, preventing accidents and minimising downtime due to equipment failure.

In fact, MDL’s range leads the way in tensioner safety, making this the number 1 priority in all our designs. The key prevailing element is the unique Failsafe Grip System, which ensures constant grip on the product even in case of a critical failure or power loss. It’s down to the special grip system design that is characteristic of the MDL tensioner range.

Myth 4: Size and pulling force are the only factors that matter

Fact: While these two specifications play a crucial role in defining the tensioner’s capability, there are various other factors to consider. Flex-lay tensioner systems need to be versatile enough to accommodate different pipe diameters, as well as handle varying tension requirements. They should offer flexibility in terms of adjustable track widths, modular design, and compatibility with different vessel configurations. Moreover, the ability to quickly switch between operating modes and adjust to changing sea states is vital for maintaining mission efficiency.

And even the topic of pulling force is not as clear-cut as it may seem. A tensioner denomination will usually indicate the top line tension it can achieve for installation within its SWL parameters; however, in reality it can rarely achieve the same top tension when retrieving the product from subsea. The culprit is the capstan effect.

The Devil in the Capstan

The capstan effect is a phenomenon that occurs during flexible product retrieval and lay operations in offshore or marine environments. It refers to the additional tension or force exerted on a pipeline or cable due to its contact with a solid and static surface, such as a steel chute.

In offshore flex lay operations, a chute is commonly used alongside a tensioner to install (over-board) a product from a vessel’s back deck into the water column or to recover products from the seabed onto a vessel back deck.

During recovery or over-boarding operations, the flexible product slides over the chute which creates friction and additional tension or force. This effect causes risks when operations take the tensioner to the maximum of its operational envelope.

When over-boarding at high tensions, greater than 75Te, the interface of the flexible product over the chute has the potential to compromise the product due to the additional forces being exerted.

When recovering at high tensions, the additional friction force of the chute increases the overall outboard line tension. If the overall line tension is greater than the pulling force of the tensioner, it may not be feasible to recover the product.

We identified this very issue when we were specifying a solution for efficient decommissioning of products from Brazil’s deep-waters. By analysing the product data and environmental conditions of the site, our client required 100-tonne pulling force to recover products onto the vessel deck. However, with a commonly used chute and Coefficient of Friction of 0.3, the tensioner needed the capability of achieving a 185Te line pull. Even if we deployed our 150-tonne tensioner, we could not achieve this line pull due to the capstan effect on the chute.

That is why we developed the Wheeled Horizontal Lay System (MDL WHLS) which eliminated the capstan effect allowing us to achieve the required line pull.

Learn more about how tensioners can be speced to suit your unique scope in part two of our Flex Lay Myths series on tensioner capabilities.

- April 2024MDL supports Saipem on Greece INGS

- January 2024Preparation is key to a long life subsea

- January 2024Forward thinking with Holland

- January 2024Ensuring peak performance for FPSO and platform owners in 2024

- December 2023Reducing the risk of cable failures