MDL Engineering Consultancy Service

Performance: made to measure

At MDL we pride ourselves on our unwavering commitment to excellence and precision, ensuring that your offshore assets can operate safely and reliably in even the harshest environments.

With over two decades of experience in managing manufacturing, flexlay and equipment life extension projects, we have a thorough understanding of the key requirements on every scope.

Tap into our creative expert talent to futureproof your assets, maximise returns from your project - or help you win it.

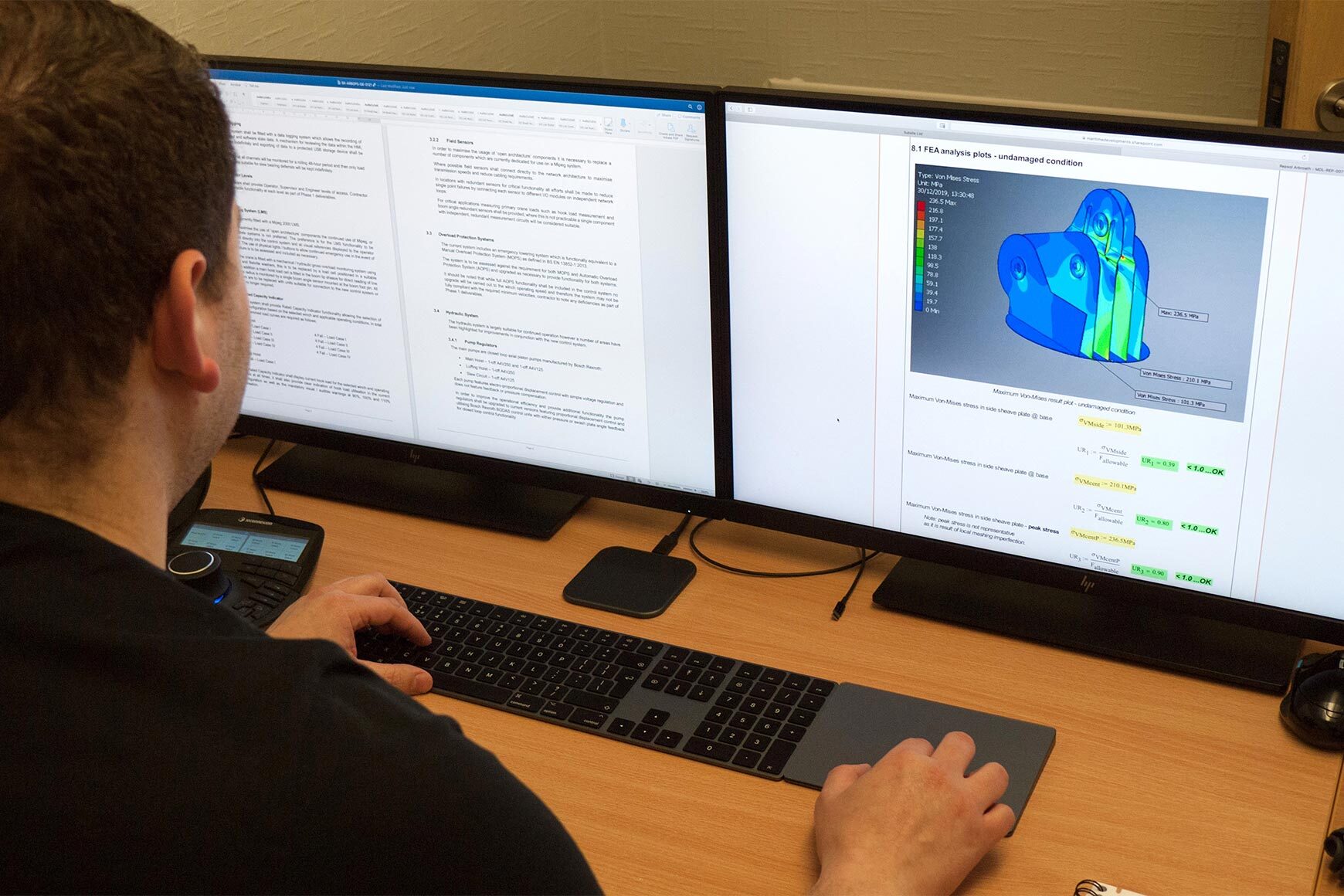

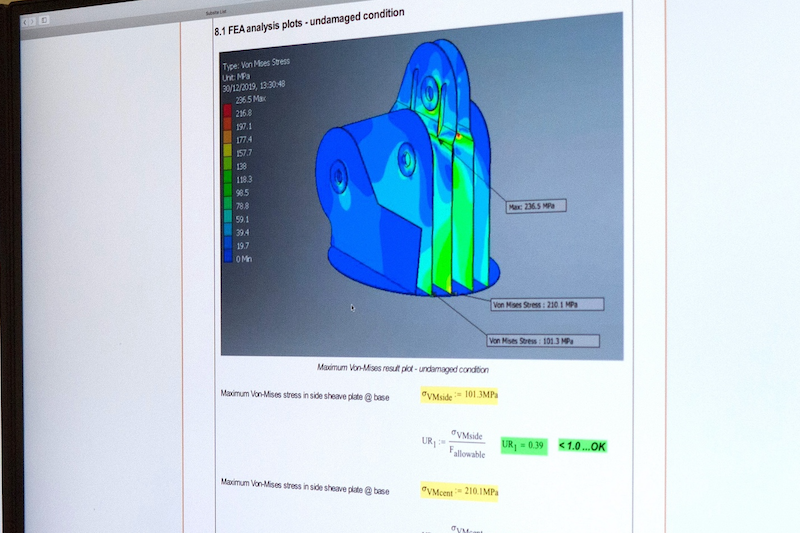

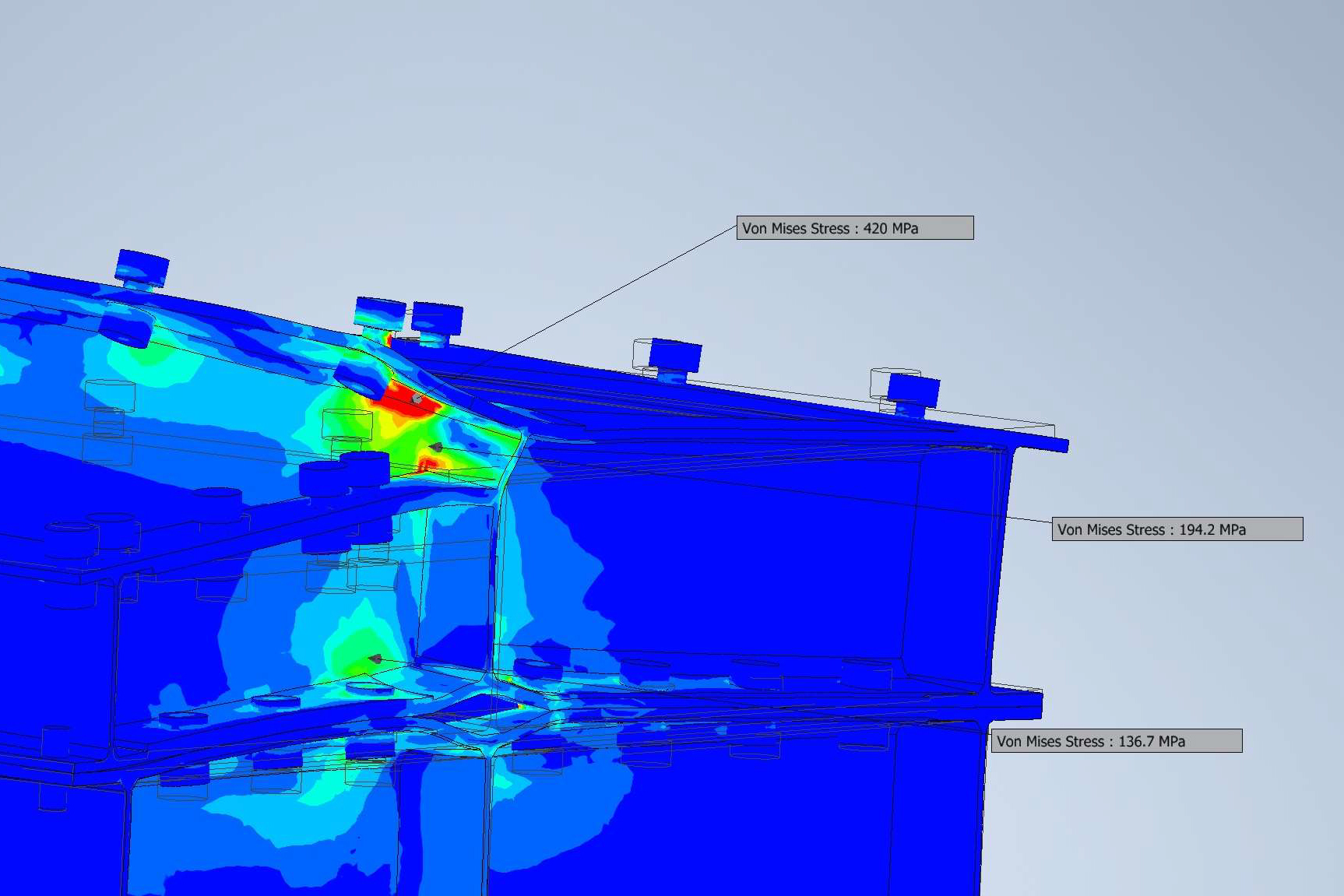

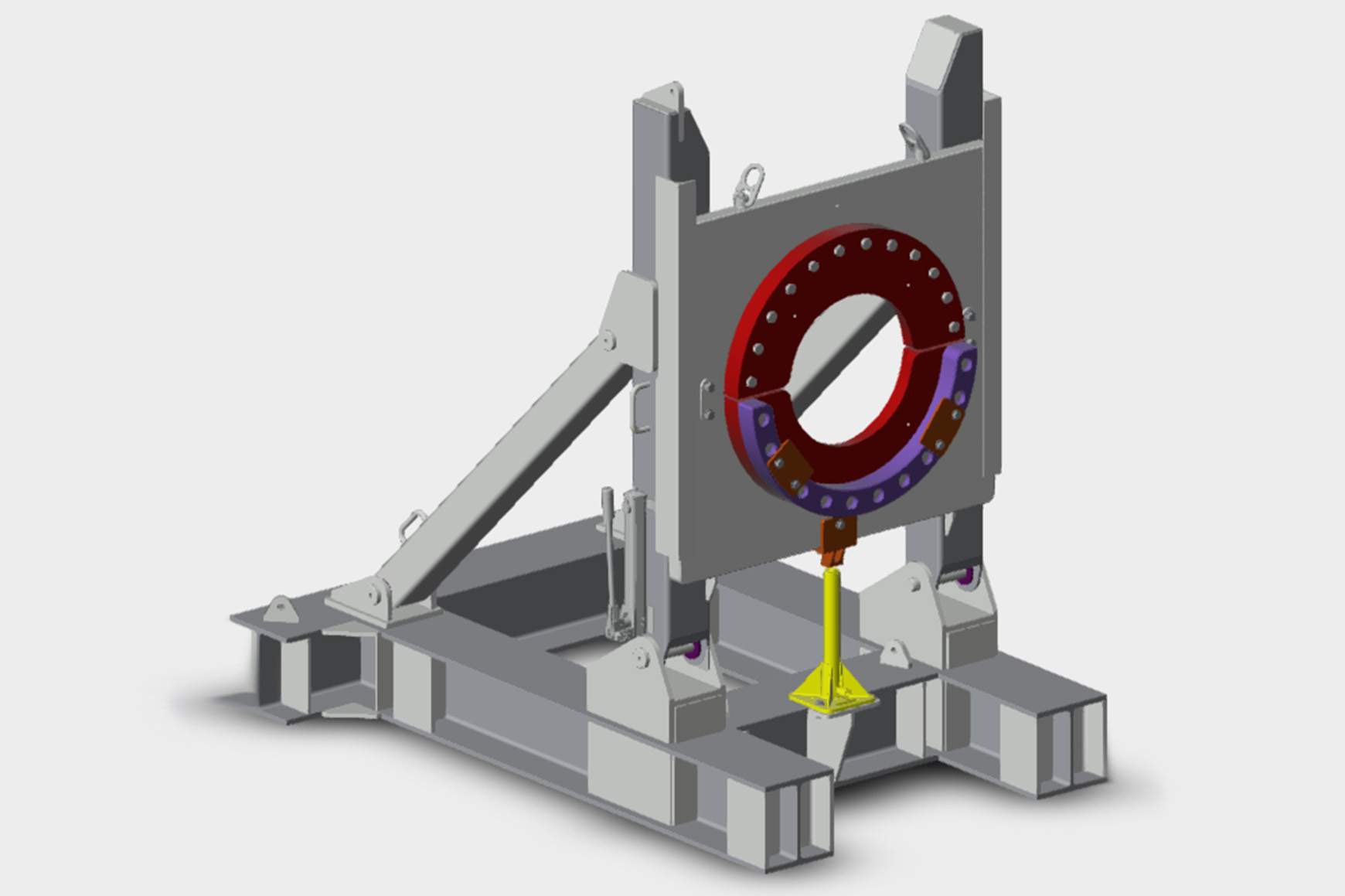

Structural analysis and FEA of offshore structures

- Structural analysis: Our process encapsulates various techniques, Computer Aided Engineering (CAE), FEA and classical approaches to evaluate structures, ensuring materials and designs can withstand external forces without compromising performance.

- Computer Aided Engineering (CAE): Through these simulations, we assess and predict how design variations will perform under real-world conditions. This lets us identify potential issues early in the design phase, saving time and resources in the development process and optimising concepts for maximum safety, reliability and efficiency.

- Finite Element Analysis (FEA): Through FEA, we break down complex structures into their elements, enabling us to scrutinise the behaviour of these under various conditions. These simulations reveal potential stress points and allow us to assess dynamic forces that could be impacting structural integrity.

The results of both of these advanced analyses provide you with a comprehensive understanding of how your structures respond to dynamic and cyclic loadings. This allows you to make well-informed decisions about your maintenance strategies and structural enhancements of your assets.

Through this approach, we can determine duty classification ratings and ensure your asset is used in line with its intended design.

Failure Modes, Effects & Criticality Analysis (FMECA)

Offshore environments are characterised by harsh conditions, including extreme weather and corrosive seawater. These conditions can place significant stress on your equipment and structures, increasing their likelihood of failure.

By identifying potential failure modes and their effects on the asset, as well as analysing the criticality of each failure mode, our team of experts can help you prioritise maintenance and repair activities. This way you can ensure that resources are allocated to address the most critical issues first.

This proactive approach to maintenance allows you to prevent costly breakdowns and minimise downtime, ultimately improving safety and operational efficiency on your producing assets.

Reverse engineering

Leveraging 20+ years of engineering expertise, our skilled team specialises in analysing complex structures to provide comprehensive assessments and recommendations for improvement - even when the original documentation is missing.

This expertise becomes crucial when dealing with outdated systems and a lack of manuals to reinstate or update them. When compounded by an unavailable OEM, these systems can quickly become a burden to you. That's where we come in: We re-engineer the obsolete components and make sure that your fleet boasts a system as good as new.

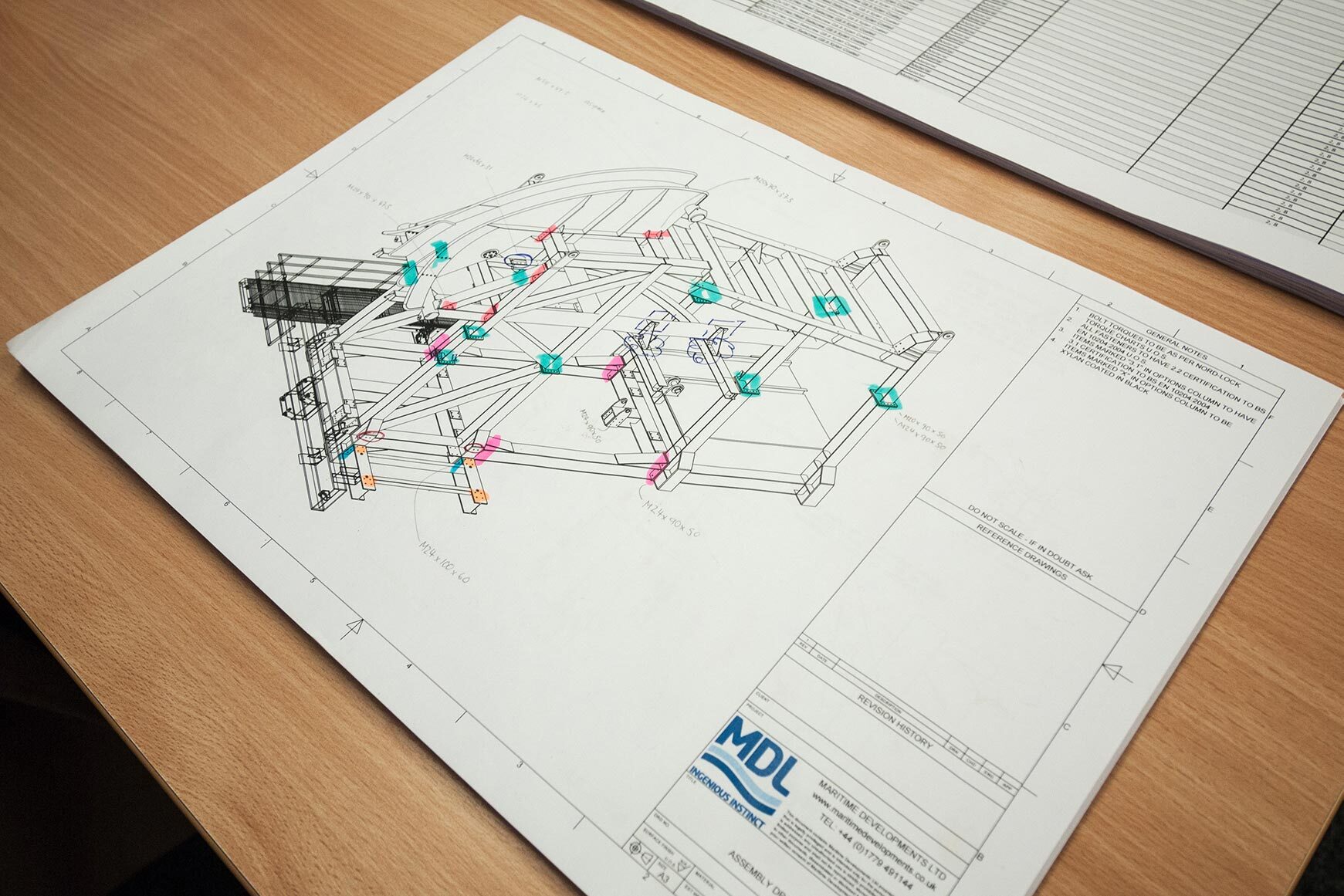

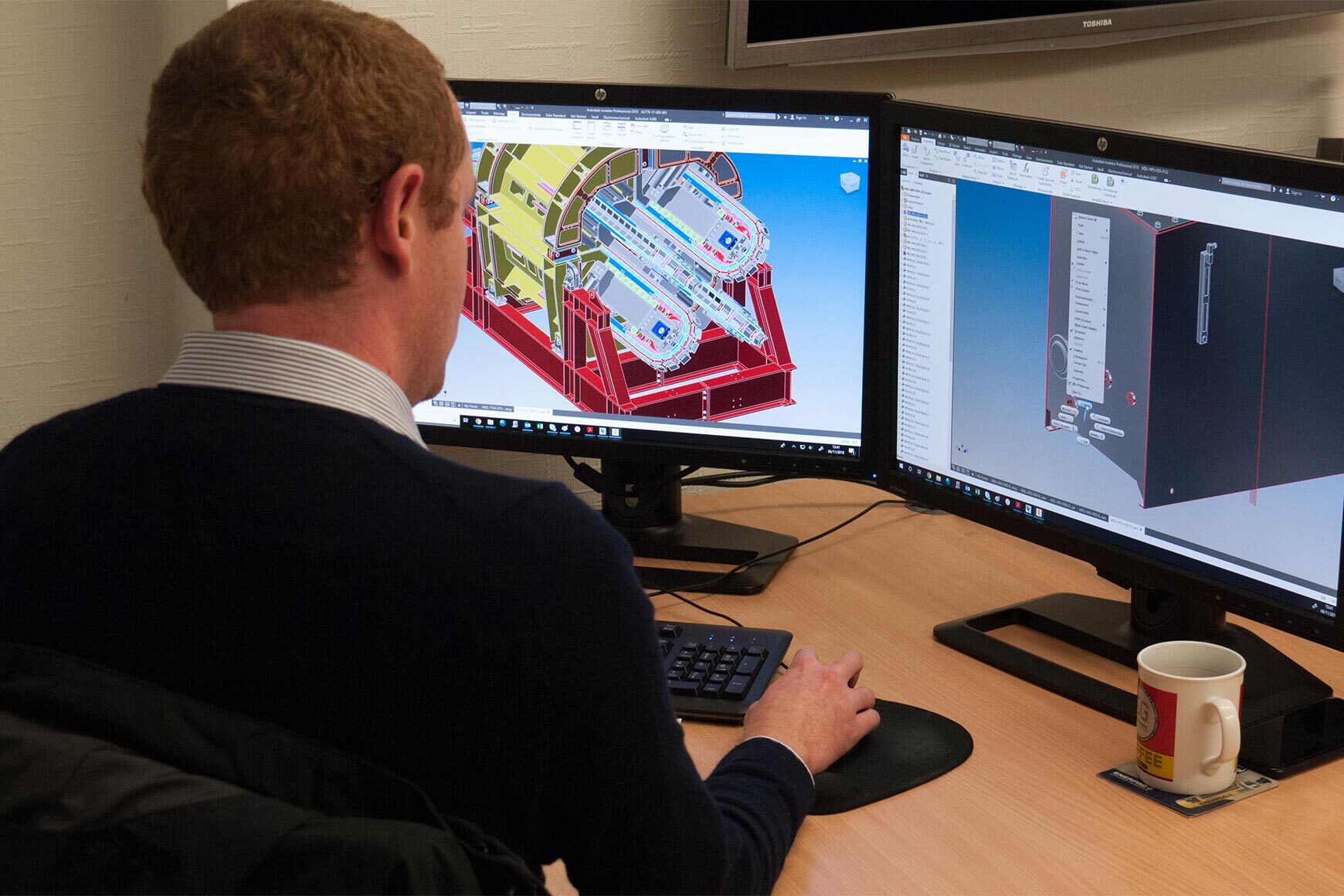

Design draughting and visualisation

The Design Draughting team supports all areas of the business: AME for asset life extension and flex-lay services during mobilisations of equipment on a multitude of vessels throughout the world.

- High quality 3D modelling of offshore equipment to support manufacturing processes

- High quality 3D visualisations, animations and renders

- Storyboard drawings and 3D render storyboards

- Detailed manufacturing drawings for machining, fabrication, assembly

- General arrangement and set-up drawings

- Vessel layout and sea-fastening drawings

- Machine part drawings

- Lifting and rigging drawings

Design codes and standards

MDL Projects team has expertise in a variety of global standards, design norms and industry requirements such as;

- DNV

- Lloyds Register

- ABS

- European and British Standard

- Nationally Recognised practices such as LOLER, PUWER

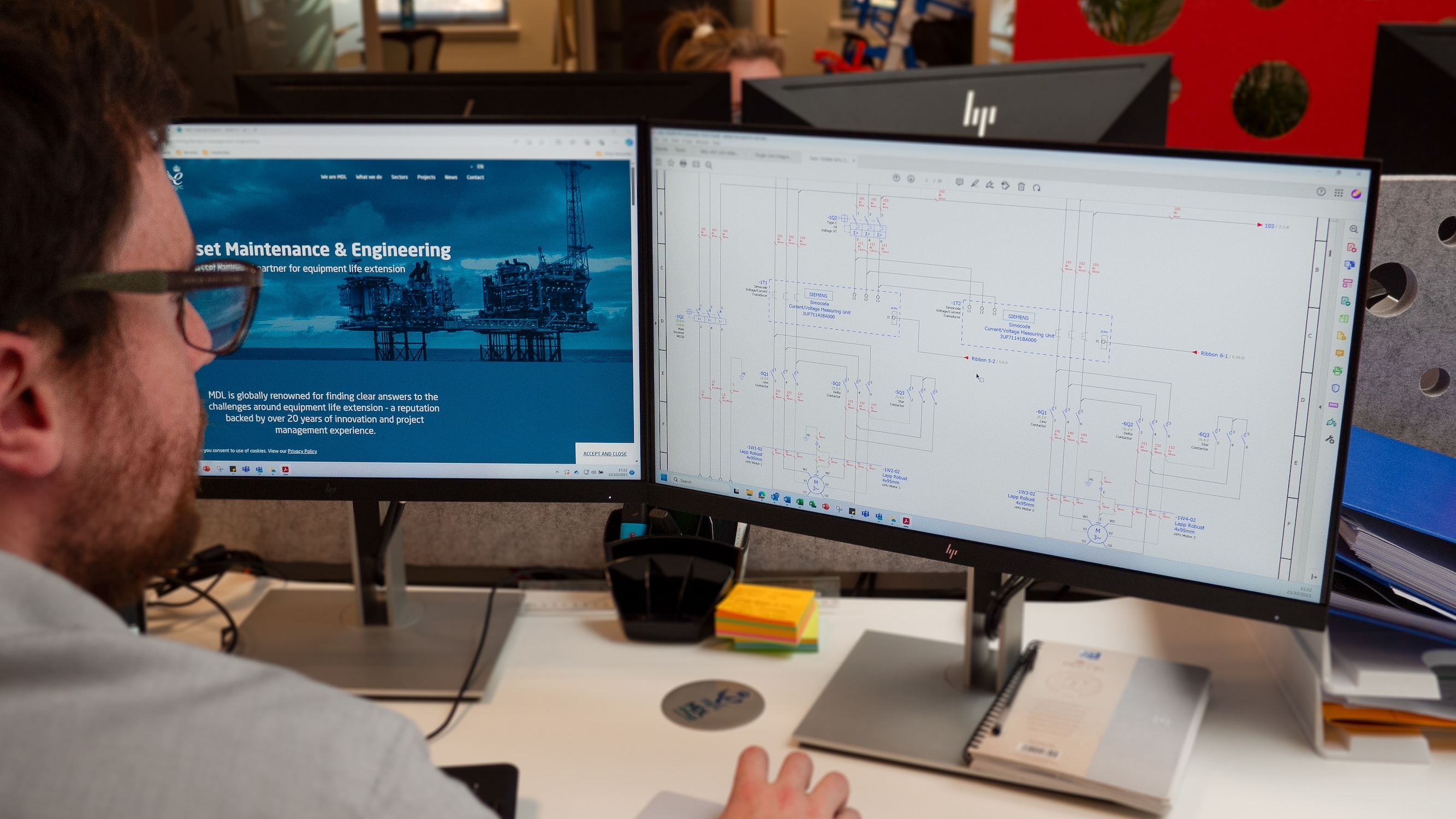

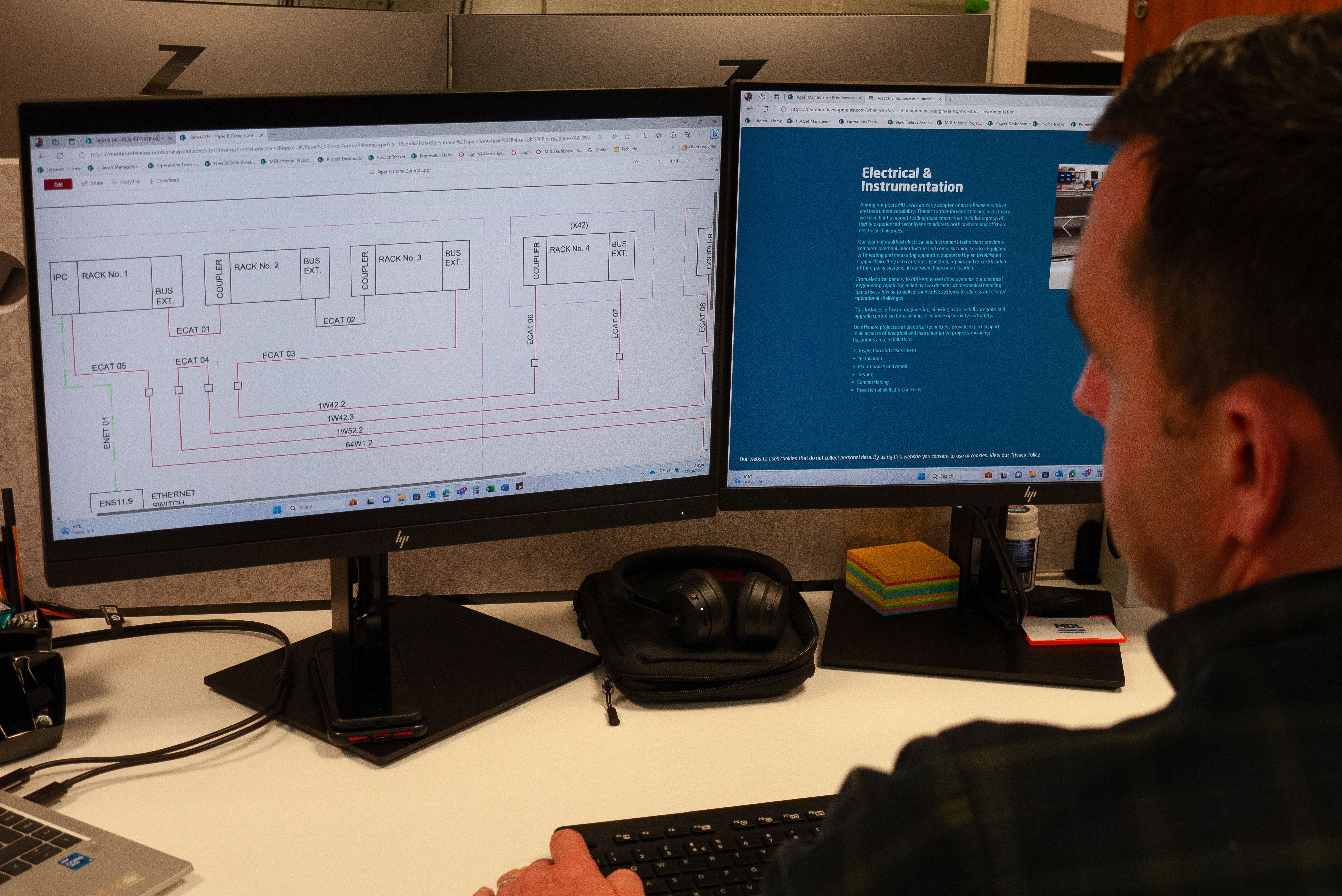

Software design

We're dedicated to enhancing your operations through our advanced software design capabilities.

- Leveraging the latest technologies: Supporting across a range of software / PLC platforms, our software design team ensures every solution blends in seamlessly with your current workflows. Engineered to enhance the capabilities of your existing third-party assets, the software maximises equipment usage and function and extends their lifespan while the expert integration with your existing systems minimises disruptions and ensures smooth operation across your entire infrastructure.

- Custom solutions: From user-friendly interfaces to robust failsafe software, MDL's solutions are designed with your needs in mind, providing a strategic advantage for your day-to-day operations.