Unlock the power of proactive asset maintenance

Preserving value while minimising costs: here's why you need to be proactive with your Asset Integrity Management.

If you operate any offshore assets, you’ll be familiar with the concept of Asset Integrity Management (AIM). We hope that you don’t see it only in the realms of obsolete or failing equipment - when done right, AIM can help you prevent breakdowns and extend the lifespan of your assets, ultimately saving you time and money.

In this guide, we'll explore the benefits of proactive asset maintenance - the key to successful AIM - and provide tips for creating a winning maintenance strategy.

AIM on FPSOs and Platforms

There are various asset integrity works that need to be carried out on floating and fixed offshore facilities to ensure their continued safe and efficient operation.

Inspection and testing of critical equipment

Production equipment, risers and mooring systems all demand regular inspection and testing to identify potential issues and address them proactively, well before they escalate into equipment failures or downtime.

Maintenance and repairs

Routine maintenance serves as the foundation of asset reliability, ensuring that equipment and structures operate flawlessly without posing any safety or environmental risks. This includes activities such as planned maintenance as well as addressing any issues identified during operation or inspection, such as replacing failed components and damaged structures.

Structural assessments

Both platform and FPSO equipment require periodic structural assessments to ensure safe and optimal operation to increase their lifespan for safe use.

Corrosion control

Platforms in particular face constant exposure to corrosive substances, posing a serious threat to their structural integrity. Implementing preventive measures is crucial to protect structures and equipment from decay and degradation.

Tactical vs Strategic AIM

The AIM activities you undertake will be a result of one of three approaches to asset maintenance, each with its own set of benefits and drawbacks:

Reactive maintenance

This involves fixing assets only when they break down. It is often seen as a quick fix since it requires minimal upfront planning or investment. However, it carries a significant drawback: the potential for costly downtime and unexpected operational disruptions. Reactive maintenance tends to be more expensive in the long run: since repairs are completed in emergency situations, they may be rushed or incomplete, leading to further breakdowns.

Preventive or proactive maintenance

This approach revolves around regularly scheduled maintenance activities aimed at preventing breakdowns and ensuring assets operate at their peak performance. The benefits are notable: by conducting routine inspections and servicing, potential issues are identified and addressed before they escalate into major problems. While it does require upfront costs for routine inspections and servicing, the investment pays off in the long run by minimising unexpected expenses and significantly reducing the risk of downtime and relating loss of revenues.

Predictive maintenance

This approach leverages data and analytics to predict when maintenance is needed, to enable more efficient and effective maintenance planning. By analysing relevant data, predictive maintenance allows for well-planned maintenance activities, reducing the chances of unexpected downtime and optimising the utilisation of available resources and schedules. Moreover, it enables you to identify patterns and trends that can enhance overall asset performance. However, implementing predictive maintenance requires access to relevant data, advanced analytics capabilities and skilled personnel. It may involve upfront costs for installing sensors, data collection systems and establishing the necessary infrastructure.

To develop a successful maintenance strategy, you can incorporate elements of all three approaches. By doing so, you can maximise the benefits while mitigating the drawbacks of each method.

Creating a Successful Maintenance Strategy

Maintaining your assets in optimal condition will reward you with safe operations and continuous return on investment. As with any long-term objective, a targeted asset maintenance strategy is key - here’s how to tailor one to your asset, and where MDL can help.

1. Assess Asset Importance

Start out by identifying your (offshore) assets and determining their criticality to your operations or business as a whole. This will help prioritise which assets require the most attention and resources. When in doubt, tap into our Project Management & Engineering (PM&E) expertise. Our team has decades of experience in managing our own asset fleet as well as integrating our newbuild systems into clients’ existing infrastructure. With this experience and knowledge, they can advise you on your system dependencies, integrations and potential impacts on other equipment from taking a unit out of service.

2. Build a Maintenance Framework

Establish a maintenance schedule and determine the appropriate maintenance tasks for each asset. This may include routine inspections, cleaning, lubrication and replacement of parts.

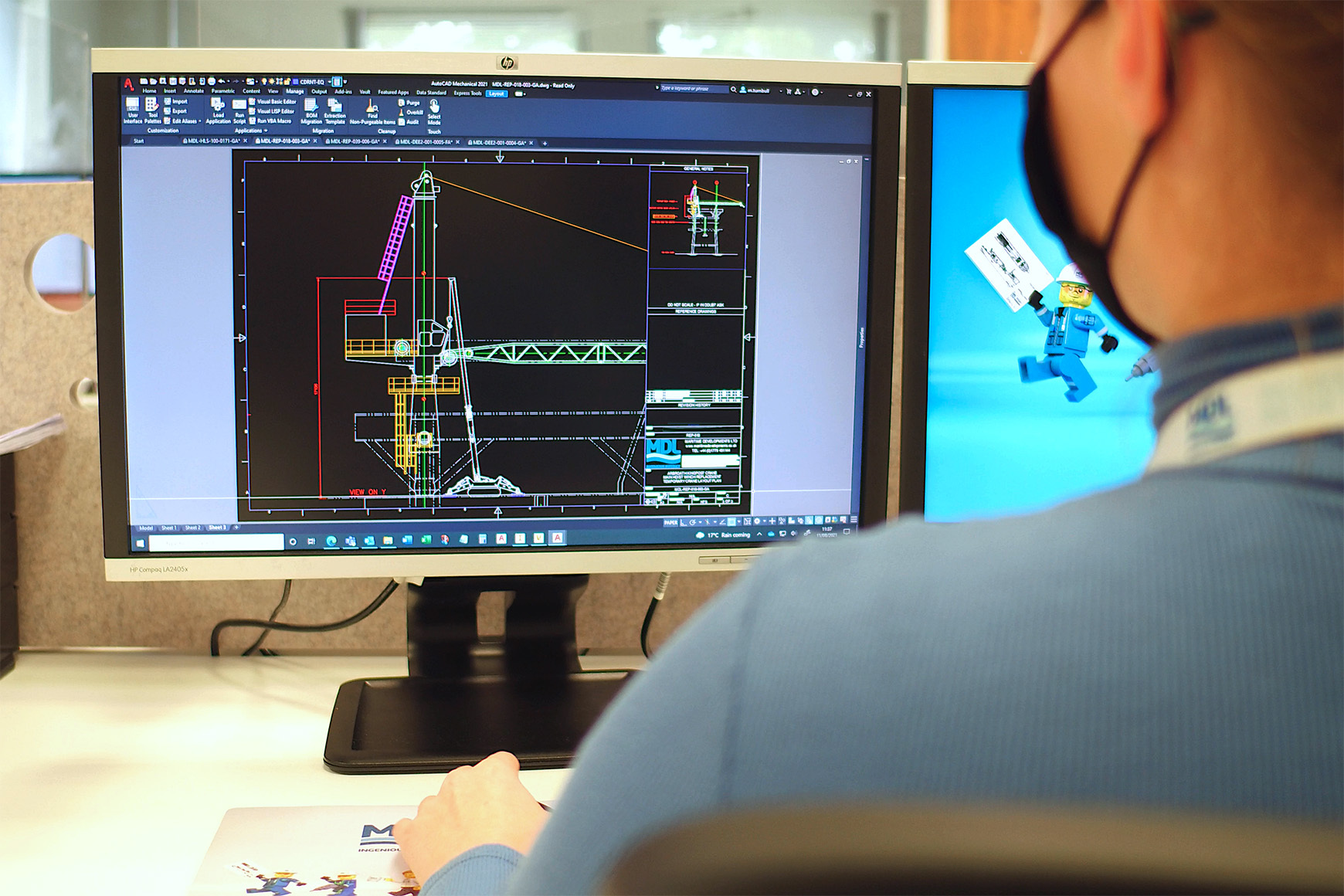

MDL technical engineers are experienced across all types of lifting and mechanical handling equipment – from hydraulic, through hybrid to fully electric, and can therefore offer efficient condition evaluation - potentially with only a visual inspection or review of the drawings.

They hold a track record in expertly identifying issues that might have been missed by other suppliers (see this case study from a North Sea platform as an example) and troubleshooting on the spot to minimise offshore trips and POB.

3. Balance Maintenance Approaches

Incorporate a mix of maintenance types into the strategy. Reactive maintenance can be minimised by implementing preventive maintenance activities, such as regular inspections and servicing, to proactively address potential issues. Additionally, leveraging predictive maintenance techniques, such as data analytics and condition monitoring, can enable more accurate forecasting and optimised maintenance planning.

Seek advice from experienced maintenance engineers, technicians or hydraulic/electric equipment manufacturers to understand safety and risk factors, review equipment upgrade options to include instrumentation and identify potential efficiencies. MDL AME team has over 20 years’ experience in designing, manufacturing, maintaining and upgrading a wide range of lifting and mechanical handling equipment. That, together with maintaining a market-leading fleet of sophisticated flex-lay equipment, has ensured our maintenance processes are streamlined, backed up with robust and regular reporting.

4. Consider Strategic Timing for Maintenance

Establish a well-defined maintenance schedule, taking into account factors such as asset usage patterns, production cycles, and business priorities - this helps in avoiding disruptions during critical periods. To support the maintenance strategy, it is crucial to invest in appropriate technologies, tools and resources, such as asset management software, remote monitoring systems and skilled personnel. We’re happy to advise on the best options based on our experience – or we can develop bespoke solutions and retrofit them into your equipment.

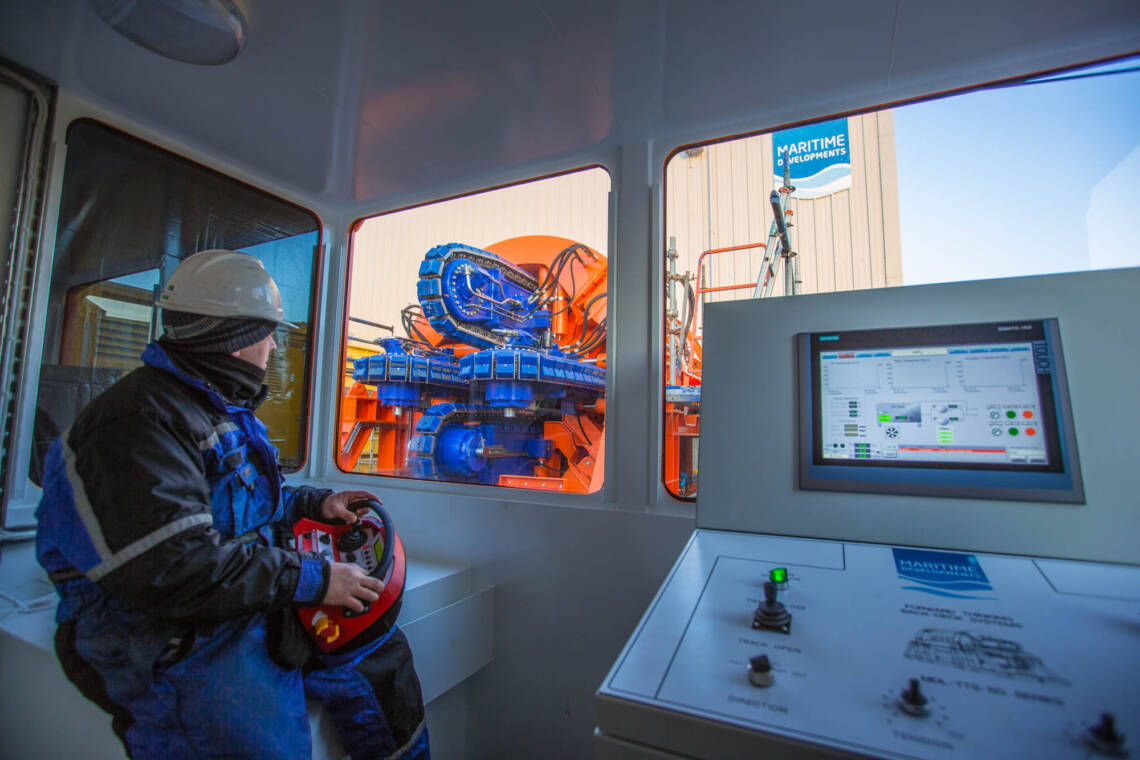

We take pride in our control systems which facilitate remote dial-up and intervention, and feature active condition monitoring instrumentation for peace of mind on our global operations.

5. Continuous Improvement and Analysis

Implement regular reviews of your maintenance strategy against your business targets or growth strategy to improve it continuously by analysing maintenance data and tracking key performance indicators. Make necessary adjustments to optimise asset reliability and ensure your strategy remains efficient and up-to-date – and at any point, use us as your sounding board. With all technical capabilities in-house, we can pull in the required skillset to provide expert advice when you need it.

The time is now to plan ahead

A well-executed maintenance strategy is an investment that pays dividends in the form of enhanced reliability, improved performance and cost savings. If you're seeking to unlock the full potential of your assets, MDL Asset Maintenance & Engineering’s all-round skillset is here to help. With over 20 years of MDL innovation and project management experience, we are ready to support you in creating your optimal asset maintenance strategy to maximising your assets' lifespan.

- April 2024MDL supports Saipem on Greece INGS

- January 2024Preparation is key to a long life subsea

- January 2024Forward thinking with Holland

- January 2024Ensuring peak performance for FPSO and platform owners in 2024

- December 2023Reducing the risk of cable failures