Safe as MDL

Strengthening the safety of oil and gas operations doesn't have to mean higher expenditure - with the right tools, H&S and cost reduction go hand in hand, believes MDL commercial director Mike Gaskin.

Ever since the tragic incident of Piper Alpha in 1988, the industry’s focus on safety has intensified, year on year.

Today, the HSEQ side of the oil and gas business has become a complex organism, with numerous regulations and processes put in place to ensure our operations are as hazard-free as possible.

However, when money gets tight in a depressed market, running this organism can put a strain on even the biggest players in the industry.

But what if increasing safety also meant reducing operation costs?

At MDL our mission has always been to solve back-deck challenges faced by our customers - from increasing efficiency to reducing operation costs.

As we’ve delivered on this mission, we’ve grown into being a market leader of our niche; and as such we recognised our responsibility to provide the safest solutions to tackle our clients’ problems.

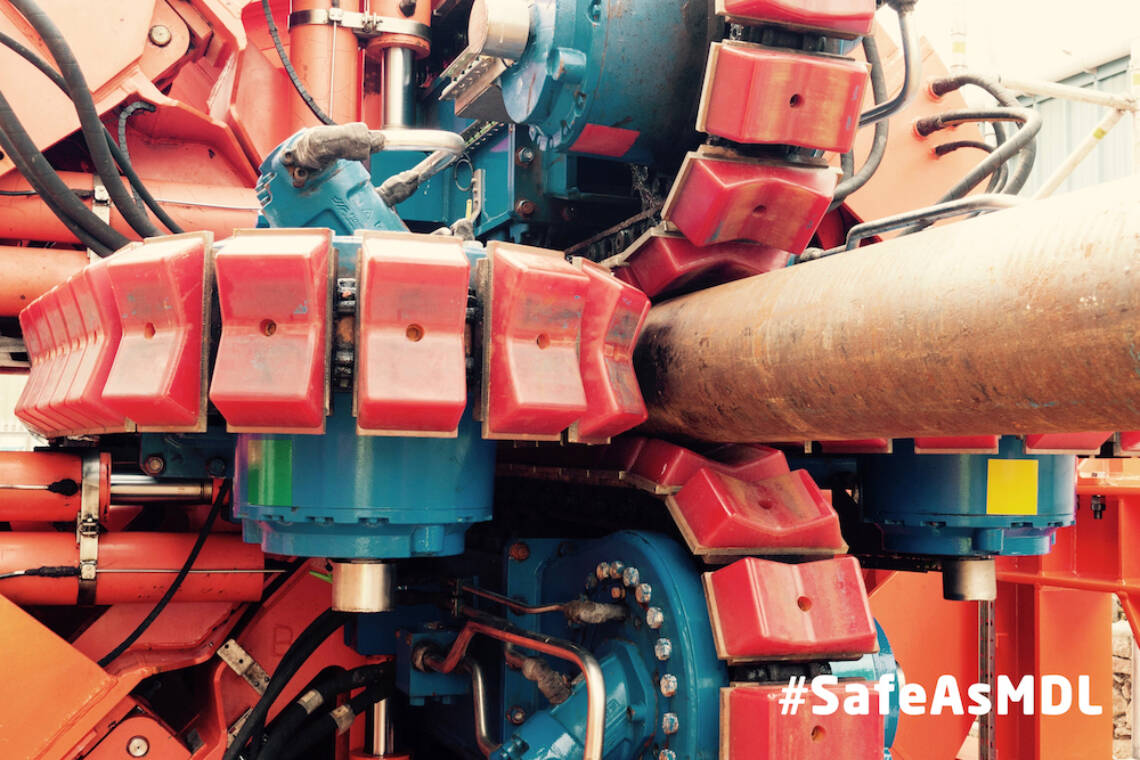

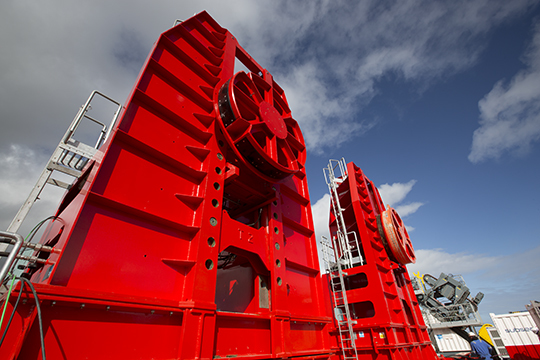

That is why we have ensured that every piece of MDL equipment sets the benchmark for hazard-free flex lay.

Let me give you an example - a traditional offshore flex-lay project requiring the use of a reel drive system.

For the reel that would be used first on the RDS, personnel had to climb inside its drum to chain the two reel drive towers together.

Once out in the field, to lift the reel off the cradles for spinning, the personnel would have to operate lock rings under the reel jacks - manually and at height.

If handling more than one reel, onboard personnel would have to manually unbolt clamps on the towers to shift them onto the next position, and then bolt them back on, to prevent unwanted movement.

The amount of manual handling involved is clear with this example - but what about the non-operational time lost in the process? Let’s look at how the MDL system addresses these:

- reel cradles integrated into MDL RDS tracks hugely speed up the product mobilisation, whilst simultaneously increasing the safety of the reels - and that of the operators who don’t have to secure the reels separately;

- the MDL towers are self-supporting - no chaining of towers required;

- automated raising and lowering system eliminates any working at heights, as all reel handling is carried out remotely; this also reduces overall mission time;

- automated walking and clamping system means the towers “walk” up the tracks to move to and securely stop by the next reel autonomously - that’s another reduction in mission time;

- controls that facilitate this automation run on the latest software developed by MDL in house. Another feature is the WAB (Walk About Box) which allows the operator to take up the most optimum position on deck to monitor the operation, whilst maintaining a safe distance from any potential hazards.

All these elements differentiating the MDL RDS from the market norm have been put in place primarily as safety features; however, as such, they also speed up the mobilisation/demobilisation in port, as well as reel handling and change-over at sea.

The combination of these elements results in a shorter mission - and therefore reduction in project cost, equal to: vessel days saved x vessel day rate.

The MDL RDS is a good example of our “cost saving through safety” approach, as the systems form part of the MDL Offshore Service, available to rent worldwide. The added reassurance with the MDL fleet is that it only includes third and fourth generation systems, which are all under three years old.

Why does age of technology matter? Think of early cars without seatbelts - would you drive one today?

To better explain the safety features of our equipment we have launched a social media campaign #SafeAsMDL; it will look in more detail into how different equipment designs affect operation, and the possible implications on project safety.

But - in line with our mission - we need to constantly improve, and find even safer ways of conducting global flex lay; so please feel free to get in touch with your concerns and problems.

Jointly, we can achieve a truly safer industry - one lower-cost step at a time.

Mike Gaskin, commercial director

- April 2024MDL supports Saipem on Greece INGS

- January 2024Preparation is key to a long life subsea

- January 2024Forward thinking with Holland

- January 2024Ensuring peak performance for FPSO and platform owners in 2024

- December 2023Reducing the risk of cable failures