Lifting the lid on AME at international crane event

MDL AME is offering a viable and cost-effective service to support offshore mechanical lifting equipment - from surveys to complete control system replacements.

MDL is exhibiting at the International Offshore Crane and Lifting Conference - the only event to focus exclusively on the offshore crane and lifting business in the North Sea and beyond.

The conference - which alternates between the “oil capitals” of Norway and Scotland – Stavanger and Aberdeen - covers a wide range of new topics in offshore cranes and lifting technology, subsea and heavy lifting, crane standardisation, and regulatory and industry safety initiatives.

During the three-day conference, attendees will have the opportunity to meet and share their experiences with North Sea offshore petroleum regulators, experts and industry leaders from the offshore crane and lifting operations community.

Ready to share their knowledge and expertise are our Asset Maintenance & Engineering (AME) Key Account Managers James Farquhar and Shaun Cooper, on stand 28.

Shaun is an experienced crane support specialist and James has more than 30 years of experience in hydraulic services and mechanical handling solutions within the energy industry.

Adding value to offshore crane owners

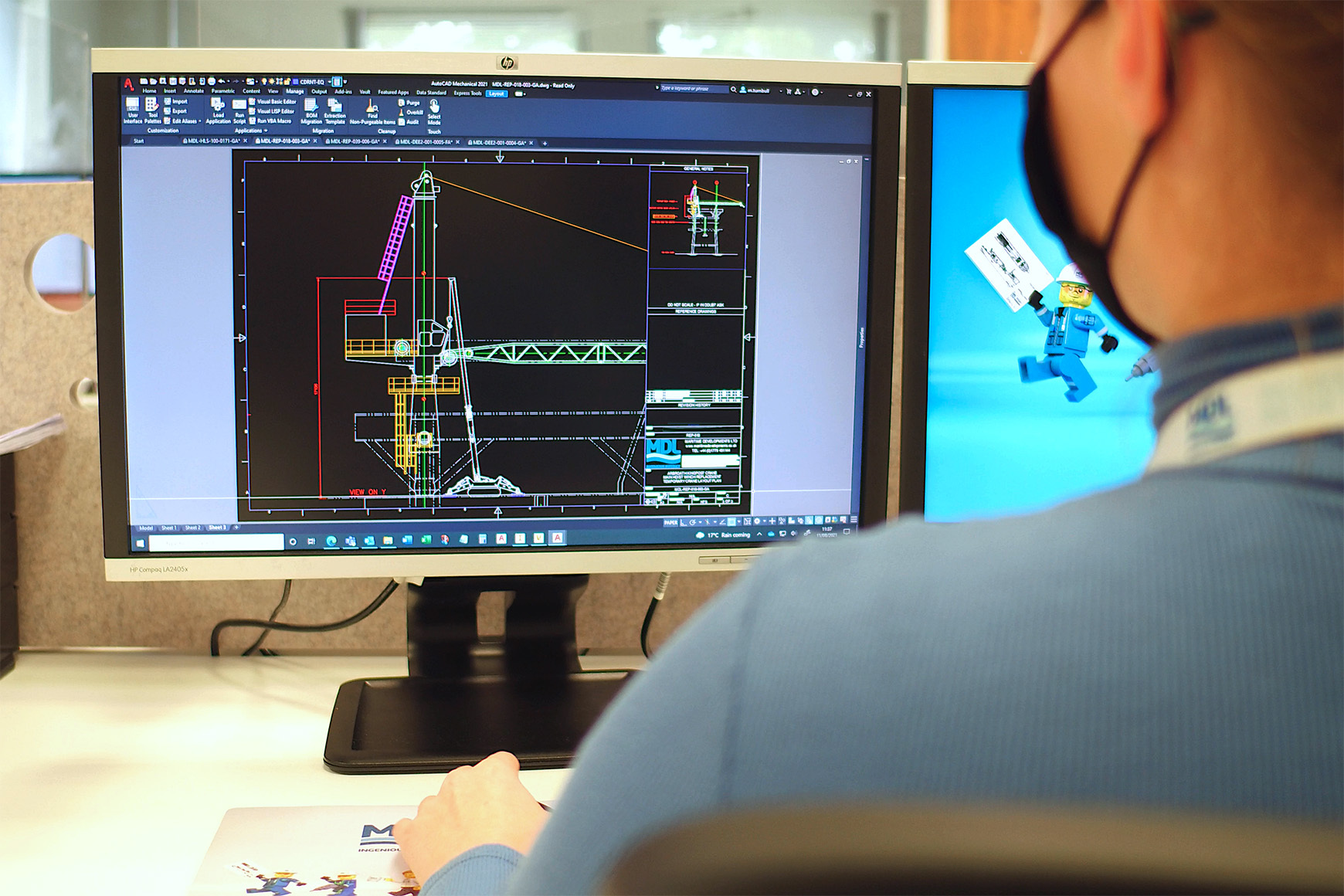

MDL’s specialist crane knowledge ranges across mechanical, hydraulic, electrical and software, and we deliver tailored solutions to tackle challenges with ageing or faulty equipment - which, apart from repairs in-situ, also includes feasibility studies, safety assessments, delivery of bespoke handling solutions and crane control system upgrades, amongst others.

MDL AME’s focus is on performing as much of the front-end Project Management & Engineering work as possible from the “desktop”, minimising unnecessary trips to an asset - demonstrating a cost aware approach, which also introduces efficiencies in the overall execution of work scopes.

We work with our clients to understand the root cause of the challenge. Then we develop an optimised execution schedule to minimise any equipment downtime - ensuring continued safe operation and efficient life extension for cranes.

A perfect example of this is the replacement of boom hoists for a North Sea Operator's fixed platform crane.

The project was a result of a prior inspection and up-front survey of the crane and asset by MDL in-house engineering team, tasked to model different scenarios to ensure continued safe operations on the client’s platform. Out of the different options, the asset owner decided to move ahead with winch replacement as the most efficient approach to safely extending the crane’s working life.

MDL AME's "desktop" deliverables included storyboard method statements, lift plans, offshore implementation work pack, commissioning, load testing and wire rope change-out procedures.

The scope included the delivery of the new winch and spare parts to MDL's Peterhead workshop, where our teams could carry out a complete interface and dimensional survey of the components to de-risk the offshore scope of work.

The MDL team carried out various pre-job briefings and site familiarisations before executing the change-out on the platform with a temporary crane - the most economical (and proven) approach.

A testament to a satisfied customer was the fact that we returned to the asset to complete the replacements of the remaining hoists - read on it here.

Specialist lifting at the core

We consider ourselves winch experts: we have been delivering these systems for over 20 years, across various marine sectors and applications in harsh environments.

The majority of the winches designed and manufactured by MDL to date have been electrically driven, operated via PLC systems and in many cases integrating with the onboard SCADA system - requiring specialist knowledge of control systems which we have honed in-house for over a decade. Our track record in bespoke software design extends to other lifting equipment - from portable reel drive systems and tensioners, to more recently complete packages of crane cab and control system upgrades for offshore platforms

The two-decade

experience of working with a variety of clients on and offshore - including

Operators and Pipelay Contractors - is reflected in MDL AME’s safety culture,

work processes and procedures, and – importantly - through consistently

delivering on targets of optimising schedules and meeting budget.

At the same time, MDL retains all the benefits of being an independent business: agility, impartiality, responsiveness and flexibility to adapt to our clients in terms of work scopes, schedules, deliverables and system processes; providing truly tailored solutions, with complete transparency from the onset - meaning no surprises at any stage of the project.

To discuss what we can do for your assets, come and speak to our team on stand 28 at the conference in Aberdeen from 29 November.

- April 2024MDL supports Saipem on Greece INGS

- January 2024Preparation is key to a long life subsea

- January 2024Forward thinking with Holland

- January 2024Ensuring peak performance for FPSO and platform owners in 2024

- December 2023Reducing the risk of cable failures