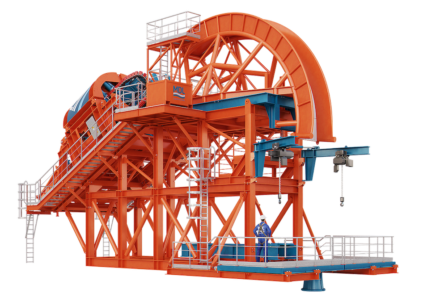

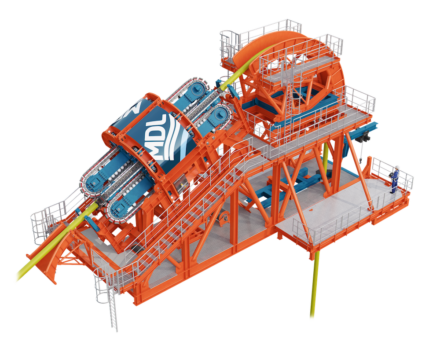

Horizontal Lay Systems

Compact and powerful spreads

For a mighty spread in a compact package you need look no further than an MDL Horizontal Lay System.

With a range of integrated features and project-specific ancillaries built within the footprint, the MDL HLS is a time-saving solution for safe and efficient deployment of long lengths of flexible and rigid pipe.

Thanks to the hydraulically operated moonpool doors and hang off beam, with optional pivoting davit arms, the systems effortlessly handle mid-line connections and buoyancy modules. The systems integrate with the complete range of MDL tensioners, to suit varying line-pull requirements and wide variety of products handled during a campaign.

Like the rest of MDL fully portable fleet, the HLS units are road-transportable, and can travel in modules to meet the products at their home ports, before being reassembled on the quayside.

All the ancillary equipment is pre-installed before the system is lifted onboard, and the HLS can be mounted either over the moonpool, the stern or either side of the vessel offering efficient mobilisation and demobilisation.

Expertise

From our design and manufacturing bases, Maritime Developments delivers product handling equipment for global energy projects.

As well as horizontal and vertical lay systems, MDL delivers the full turnkey package of back-deck equipment including tensioners, reel drive systems, overboarding chutes, spoolers, level winders, compensators and control systems.

Safety & Operational Excellence

Our horizontal lay systems are designed and manufactured to comply with PUWER / LOLER requirements. The tensioner control systems are designed for safe, efficient product handling with data logging as a standard feature. This ensures instant access to critical product lay information with the option to record the data which can be accessed during or post operation.

Design Considerations

- Type of vessel / operating conditions

- Deck mounting (overside/through moonpool)

- Vessel deck loading capacity

- Maximum installation and recovery loads

- Product outer diameter

- Co-efficient of friction of the product

- Operating product line speed