Asset Maintenance & Engineering

Trusted partner for equipment life extension

MDL is globally renowned for finding clear answers to the challenges around equipment life extension - a reputation backed by over 20 years of innovation and project management experience.

Our complete in-house capabilities allow us to survey, inspect, repair, maintain, upgrade and operate existing equipment. We can also specify, design, build and integrate new equipment, to suit a specific set of requirements.

Thanks to this comprehensive skillset, complemented by our project-focused mentality, trusted track record, and proactive and open customer approach, we can help our clients ensure their equipment is safe to use and maintained to the correct standards, maximising operational uptime.

Project Management & Engineering

From an experience of managing manufacturing, equipment provision and maintenance projects spanning over two decades, we have a thorough understanding of the key requirements on every scope: delivery on schedule and to budget.

We are a bespoke solutions provider, with the technical know-how to analyse the challenge and prepare a scope of work tailored specifically to the asset and client.

Our in-house design and delivery is underpinned by compliance with legal requirements, certification by verified industry bodies, supported by regular and consistent communication, including detailed progress reporting.

The MDL Engineering team has accreditation with IMechE, IET, IMarEST at chartered level, and is experienced in delivering complete scopes of work: from office-based studies, to on-site execution.

- Project Management & Engineering support

- FEED Studies

- Technical Risk Evaluation (FMECA, PUWER, LOLER etc)

- Chairing HAZIDs & HIRAs

- Integrated planning approach to procedures and development of offshore Work Packs

For examples of our PM&E expertise, check out our FPSO or Transpooling case studies.

Crane Maintenance & Integrity

MDL’s in-house crane specialists' knowledge base across mechanical, hydraulic, electrical and software ensures we deliver tailored solutions to challenges with ageing or faulty equipment.

We work with our clients to understand the root cause of the challenge, and develop an optimised execution schedule to minimise any equipment downtime - ensuring continued safe operation and efficient life extension for cranes.

We start with “desktop” front-end planning to define the overall work scope and develop optimised schedule for delivery of components and the offshore execution, before deploying experienced, multi-disciplined technicians to safely execute the maintenance/repair in line with OEM requirements and adhering to the asset's processes and procedures.

- Inspection / assessment

- Maintenance and repair

- Operability optimisation

- Equipment upgrade

- Load testing

- Provision of multi-disciplined technicians and operators

Learn more about our recent crane maintenance projects.

Winch Expertise

We consider ourselves winch experts: after all, we have been designing, delivering and overhauling these systems for over two decades, across various marine sectors and applications in harsh environments.

Our track record covers production and drilling platforms, FPSOs and a wide range of vessels, including deck winches, BOP, riser pull-in, tugger, anchor handling, hawser and offload winches as well as crane hoist winches.

We prioritise “desktop” engineering for maximum efficiency and optimised POB; and, with the complete technical skillset in-house, we can maintain, repair, commission and test on-board systems - wherever possible, without bringing them ashore.

- Inspection and fault finding

- Maintenance and repair

- Equipment upgrade

- Winch dismantling, procuring and re-assembly remotely or in-situ

- Offshore installation and integration

- Wire rope change-out under tension

- Complete function / load testing

- CompEx recertification

- Provision of multi-disciplined technicians and operators

- 5-year maintenance programmes

Browse our in-house winch designs or view some recent platform project case studies.

Mechanical Handling

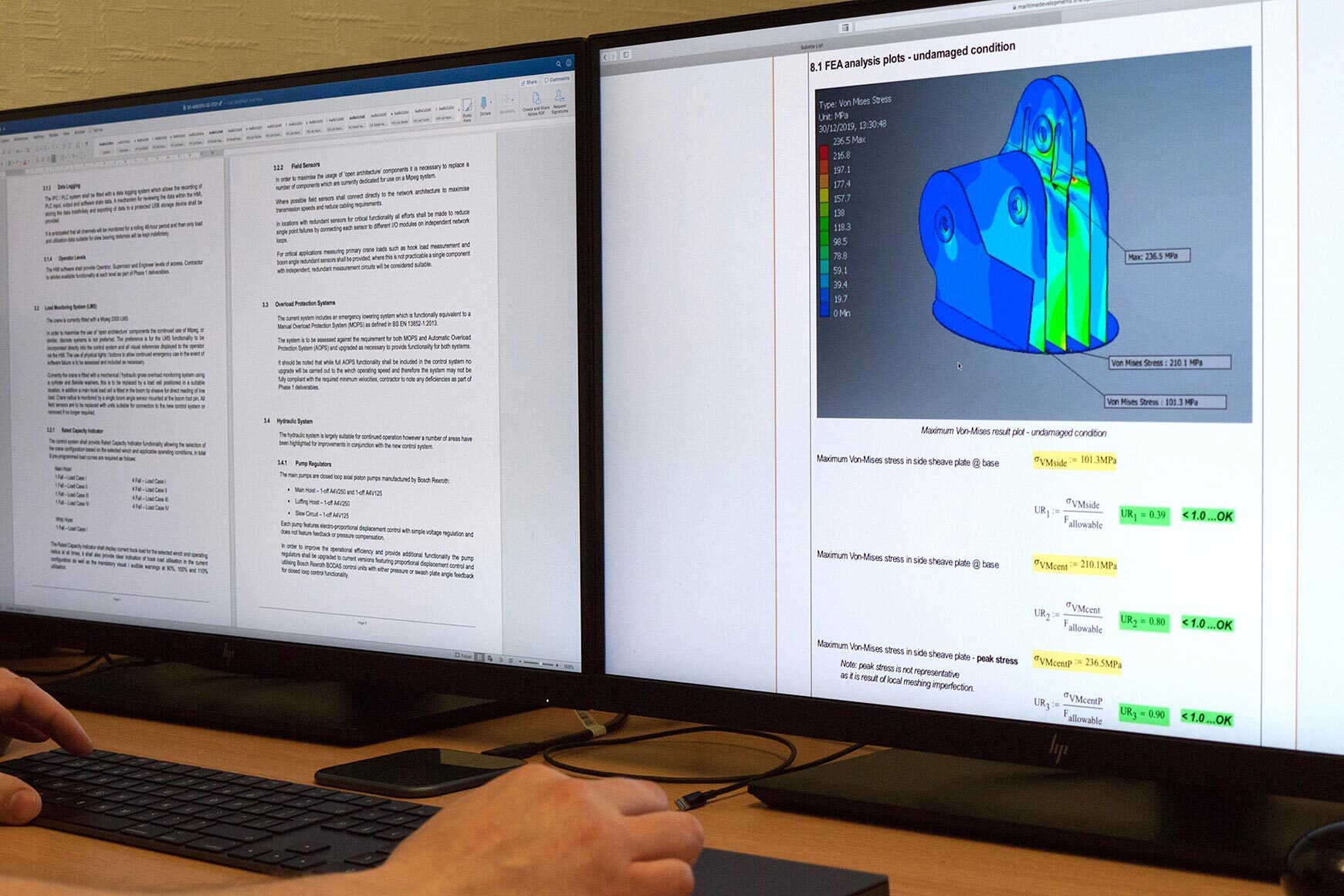

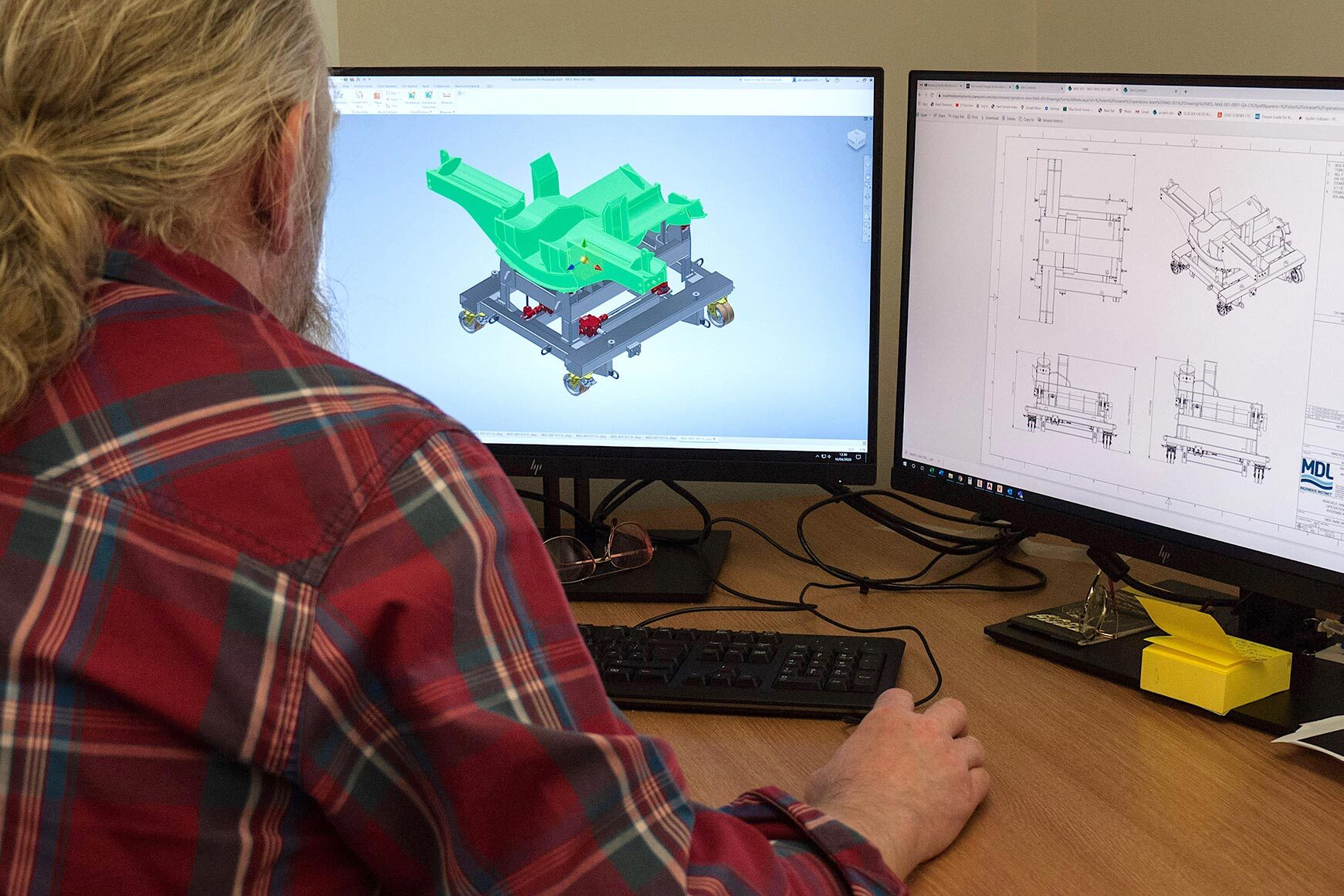

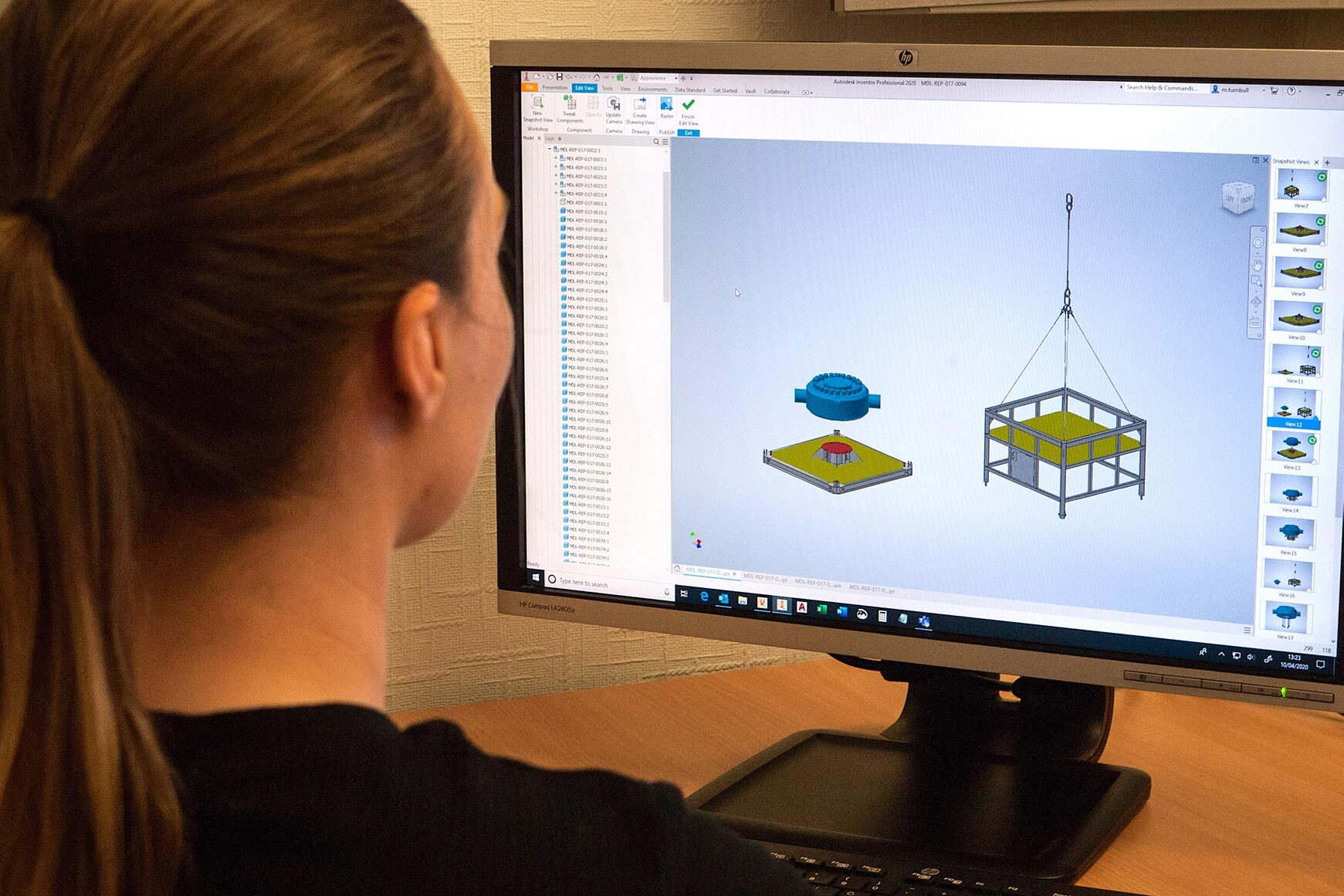

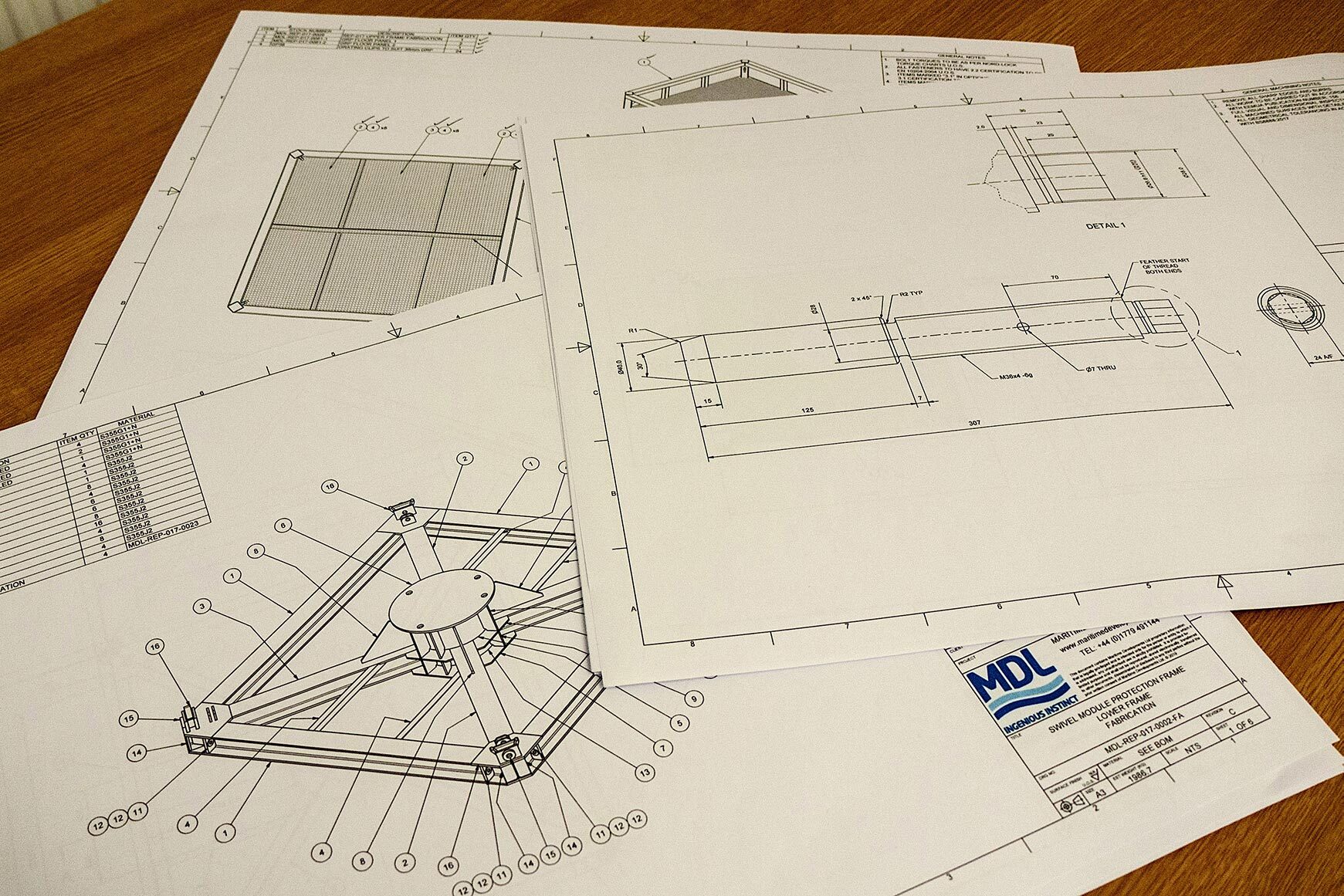

With a 20+ year track record in designing, delivering, operating and overhauling mechanical handling equipment, we have the experience and in-house expertise to address our clients' challenges and ensure we develop a safe and cost-effective method of execution.

Our multi-discipline engineering team will work with our clients to identify a targeted solution for the challenge at hand: from modifications and upgrades, to bespoke design - including feasibility studies, through detailed design, procurement, manufacture and integration testing.

- Handling studies and risk mitigation

- Inspection / assessments

- Maintenance / servicing

- Bespoke design and manufacture

- Lift plan development

- Storyboard development

Find some examples of our own-design mechanical handling systems under the Newbuild Equipment projects and other case studies.

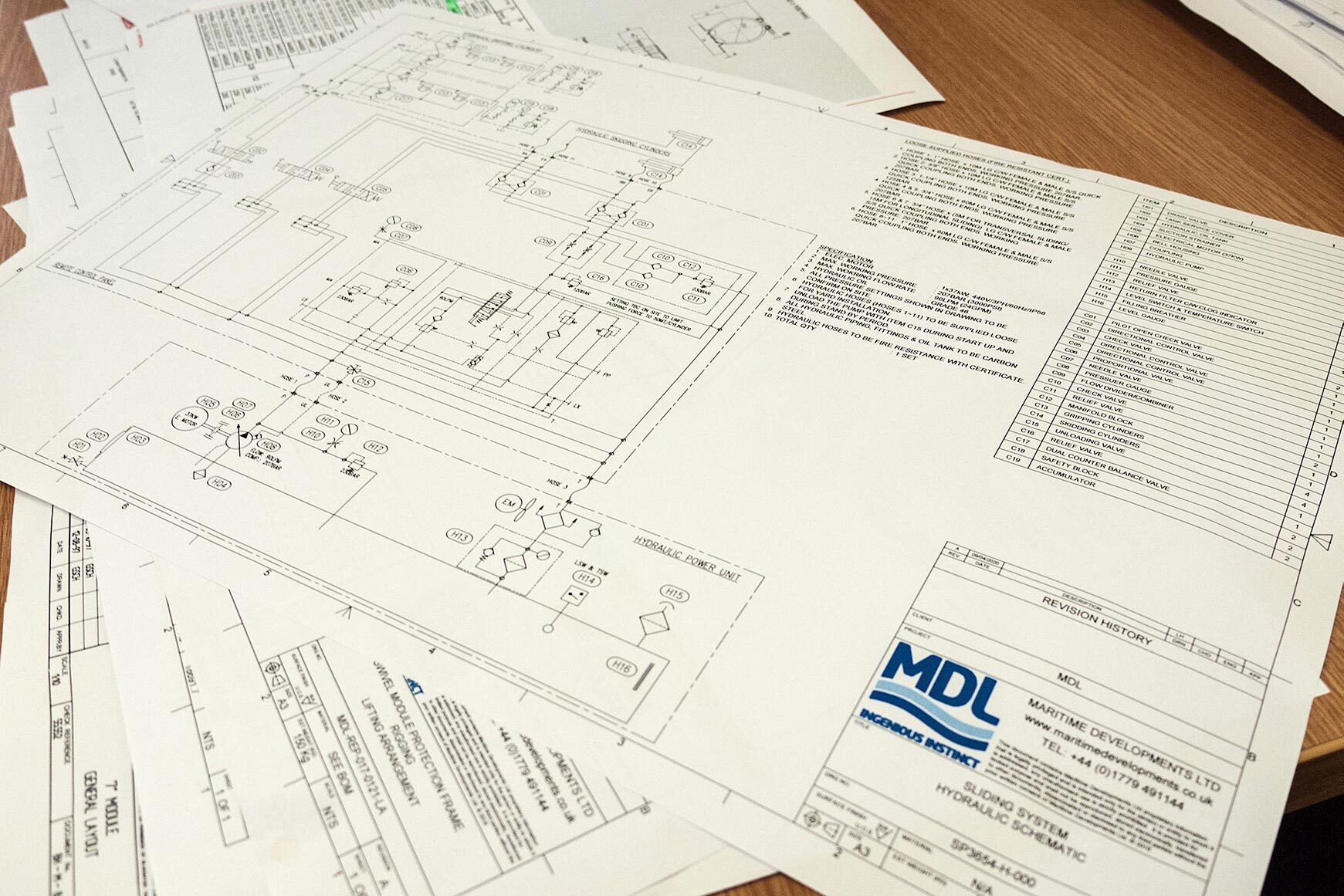

Hydraulics

From our roots supporting the fishing industry, hydraulic systems have been core to our business. Our engineers and technicians are highly experienced in design, installation, maintenance and overhauls of hydraulic-driven units, control systems and single components.

We specialise in system reviews, design and development; hydraulic power unit maintenance; pipework, hoses and fittings maintenance; circuit flushing; motor and gearbox overhauls; and hydraulic and air control valve inspection and testing.

Our portfolio of equipment reinstated to safe and fully operational condition includes winches, subsea handling systems, cranes and pipelay equipment.

- System consultancy

- Component sales

- Equipment refurbishment

- Equipment design and manufacture

- Equipment hire

- Hot oil flushing and pressure testing

- Field service

- Troubleshooting

- Small bore tubing and pipework installation

Visit our Newbuild Equipment page for complete MDL deliveries of complex hydraulic units.

Electrical & Instrumentation

Among our peers MDL was an early adopter of an in-house electrical and instrument capability. Thanks to that forward-thinking investment, we have built a market-leading department that includes a group of highly experienced technicians to address both onshore and offshore electrical challenges.

Our team of qualified electrical and instrument technicians provide a complete overhaul, manufacture and commissioning service. Equipped with testing and measuring apparatus, supported by an established supply chain, they can carry out inspection, repairs and re-certification of third-party systems, in our workshops or on location.

From electrical panels, to 800-tonne reel drive systems: our electrical engineering capability, aided by two decades of mechanical handling expertise, allow us to deliver innovative systems to address our clients’ operational challenges.

This includes software engineering, allowing us to install, integrate and upgrade control systems aiming to improve operability and safety.

On offshore projects our electrical technicians provide expert support in all aspects of electrical and instrumentation projects, including hazardous area installations.

- Inspection and assessment

- Installation

- Maintenance and repair

- Testing

- Commissioning

- Provision of skilled technicians