Transpooling Case Study

Flexible handling: for storage and disposal

Reducing onshore storage costs

Challenge

Sometimes the small outgoings can turn into a big bill. Realising this, a North Sea operator reviewed their onshore assets and identified an opportunity for cost savings: through discarding of a disused product, and transpooling of others.

MDL Solution

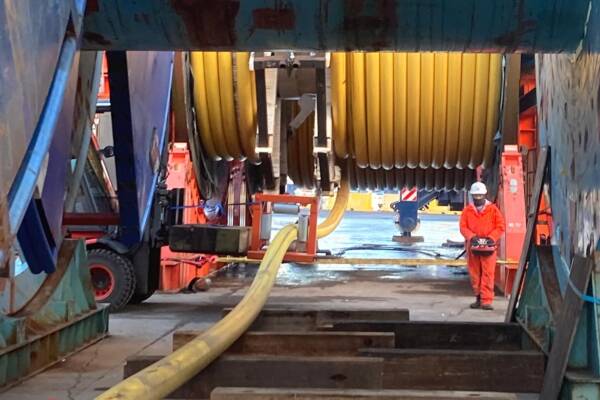

The first scope was to safely recycle an unused flexible riser, which was costing the operator storage without bringing in value. The second scope was to transpool 643m of risers stored in Denmark from costly reels hired from Europe onto MDL’s newly refurbished and re-certified reels. MDL took care of complete Project Management of both scopes including method statements and HIRAs, organising all portside services for mob and demob of reels and provision of equipment for product handling. The decommissioning scope also covered depressurisation before disposal and product recycling.

Outcomes

MDL also took care of the reels' shipping collection on both projects and the return to owners in Europe. MDL reels used for long-term storage of the transpooled product had been re-certified prior to the operation, for additional peace of mind. The reels were placed at MDL’s Peterhead quayside facility, at a fraction of the original cost – ready for quick mobilisation and deployment whenever they are required in-field.