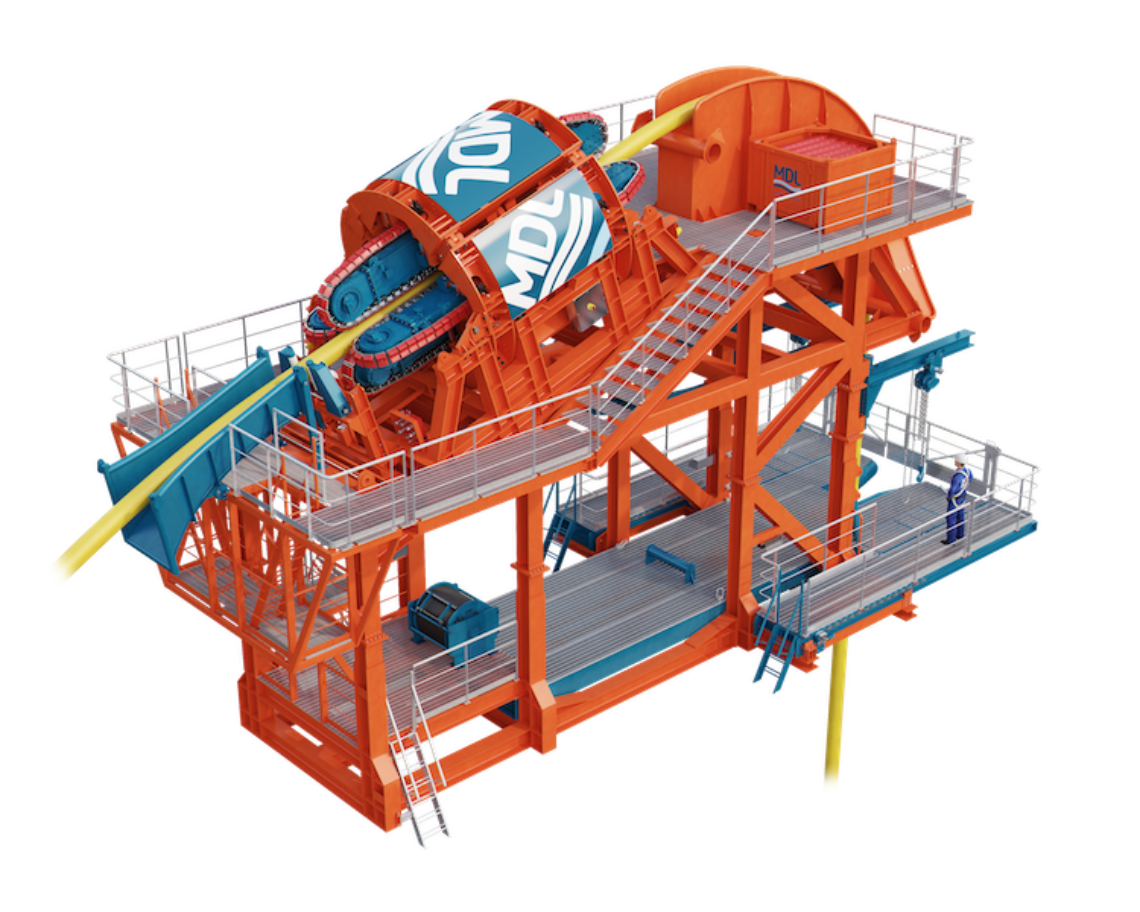

HLS-200

The MDL HLS-200 is a portable horizontal lay system for the deployment and recovery of subsea umbilicals, risers and flowlines (SURF).

The system allows for safe and efficient deployment of product from on-deck reel drive systems and carousels.

Operational Specification

Lay spread type

Portable Horizontal Lay System

Dimensions

17.6m x 6.8m x 10.0m (LxBxH)

Weight

83Te excluding tensioner

Clearance between overboarding chute and support table

4.0m

Clearance between runway beams and work table

3.7m

Clearance between davits and work table

3.2m

Product Handling Requirements

Maximum product tension

51Te (dynamic load)

Product diameter

50mm - 600mm OD

Overboarding chute radius/capacity

3.75m/50Te

Inboard chute radius/capacity

4.0Te/5Te

Runway beams capacity

3Te fitted manual beam trolley

Hydraulic davit beams capacity

180º coverage/2Te manual beam trolleys

Emergency hang off padeyes capacity

30Te SWL (combined)

Lifting Equipment

All items supplied with integrated lift points and swivel lift eyes.

Optional spares/workshop container can be supplied.

Power Requirements (HLS only)

3 phase, 440V (+earth), 60Hz

140amp supply

55kW HPU required

Assumed Conditions

Humidity

Up to 100%

Atmosphere

Marine/high salinity

Design temperature

Operational: -10ºC to +50ºC

Survival: -20ºC to +65ºC

Additional Information

Modularity: A modular system that is road transportable for economical road/sea transport.

Easily mobilised: Assembled on the quayside and lifted on board in one lift for the HLS, and second lift for the tensioner.

User friendly: The main HLS structure combines a tensioner frame, overboarding chute and moving work table. The system also has a low tension chute and integrated runway beams & davits for buoyancy installation/removal. Pad basket storage located beside the tensioner to provide access for safe and efficient tensioner pad change out when offshore

Accessible: All operational areas of the HLS are accessible by ladders and platforms, complete with handrails. Sufficient lighting throughout to facilitate 24-hour operations with an integrated power supply.

Versatility: Designed to integrate with MDL range of tensioners up to 50Te line pull.

Project Focused: The HLS structure and work table system have integrated 10Te SWL swivel hoist rings to aid product handing operations.

Safe: E-stops are mounted at each end of the HLS base frame allowing for safe control of operations.

Optional Extras: As each project has different requirements, the following optional extras can be supplied with the HLS:

-

4.2m radius overboarding chute insert.

-

2x2Te SWL hydraulic davit arms, complete with 180 degree pivot to aid jewellery handing.

-

Samson Post with sheaves for direction change for lowering and recovering ends via an A&R winch system.

-

Integrated pull-through 10Te SWL winch.

-

Dedicated 3.75m radius deck deflector with firing line adjustment of 3.2m via hydraulic cylinder system.

-

Centraliser tulip.