LiveWire Spread

Wire Rope Inspection System

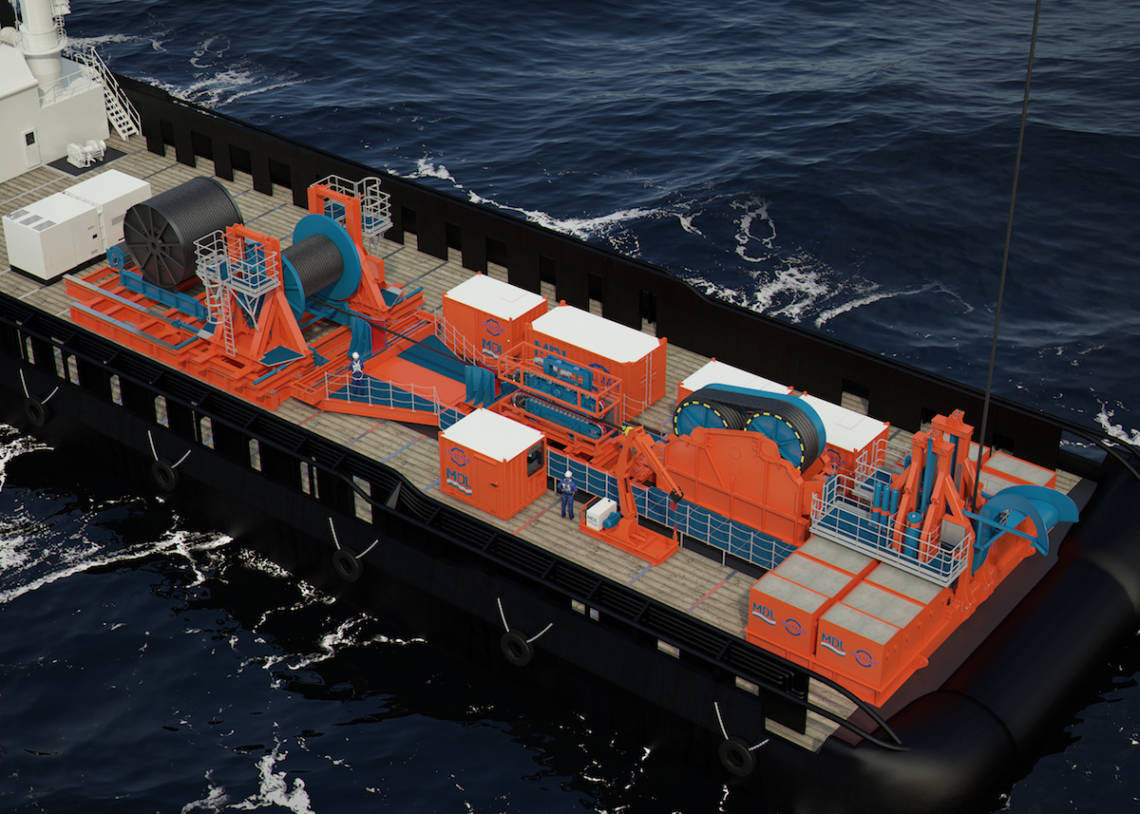

LiveWire is an integrated system for inspection, maintenance and change-out of wire rope.

The complete spread is combined of a Multi Reel Handling System, Tension and Inspection Units, Compensation Unit and Ballast Weights, as well as Non-Destructive Examination (NDE) inspection and lubrication systems.

Key Features

- Adjustable constant back tension up to 80Te

- Accommodates wire diameter up to 120mm

- Handles multiple wire storage reels up to 300Te and 6.8m diameter

- Offshore solution capable of handling vessel dynamics

- Integrated NDE inspection and lubrication systems

- Modular and road-transportable

Multi Reel Handling System

The RDS pallets incorporate an automated walking system built into the RDS towers to allow easy transfer between reels, as well as a transverse skidding function to accommodate a large range of standard wire rope reel widths.

The main drive system is fitted with a wire rope reel adapter, providing torque to the drums via two drive pins. An optional drive hub can be supplied for use with larger reels.

The integrated reel cradles allow reels to be positioned on the pallets and seafastened using the supplied clamps and connection points, preventing the need for welding to the vessel deck. Each RDS pallet also includes lifting points with sufficient capacity to lift the pallet, fully loaded reel and RDS assembly onto a vessel in a single lift, significantly reducing mobilisation time.

In addition, the Multi Reel Handling System also incorporates a wire guide system allowing the spooling of wire to be controlled underneath other reels mounted to the system. At the exit of the handling system a powered spooling unit is provided to assist with correct spooling of the wire onto and off the reels. The spooling unit uses low friction polymer material to prevent damage to the wire rope during spooling.

Tension and Inspection Units

The system is combined of a main traction winch and back tension unit to ensure sufficient tension applied to the rope throughout spooling.

The main unit comprises of a twin drum traction winch, providing a line pull of up to 80Te. The winch incorporates constant tension and render modes, as well as full manual operation with control of line tension and speed.

The back tension unit comprises of a 2-track tensioner with a selectable load capacity of 6/12Te. The tensioner features the MDL Failsafe Grip system.

The wire rope inspection unit is positioned between the tensioner and traction winch, where the wire position is fixed – this provides optimum operation of the inspection unit for highly accurate data.

Compensation Unit and Ballast Weights

Variable sea-state conditions offshore translate into vessel dynamics that can differ within the operational window, making it impossible to predict the vessel motion during inspection.

The LiveWire Compensation Unit mitigates these motions by incorporating a passive heave compensator into the system, which will adjust its position in response to varying line loads caused by vessel movements.

The use of a compensator provides a stable line tension and therefore assists optimum spooling and tensioning at the client winch.

The certified ballast weights are designed to minimise sea-fastening requirements while also acting as test weights for load testing when required.

Ancillary Equipment

To ensure smooth running of the spread, a crane is provided to assist with the handling of wire rope sockets through the system and also movement of spares and equipment as required.

The LiveWire spread is operated by three Hydraulic Power Units (HPUs) and all operated from a single control cabin via an integrated PLC network.

Wireless Walk About Boxes (WABs) are also provided, allowing control from any location on deck facilitating monitoring of critical operations and performing maintenance tasks with ease.

The LiveWire spread is powered in its entirety via a deck-mounted generator, preventing the need for connection to any vessel services – this greatly increases the number of vessels on which the spread can be deployed.