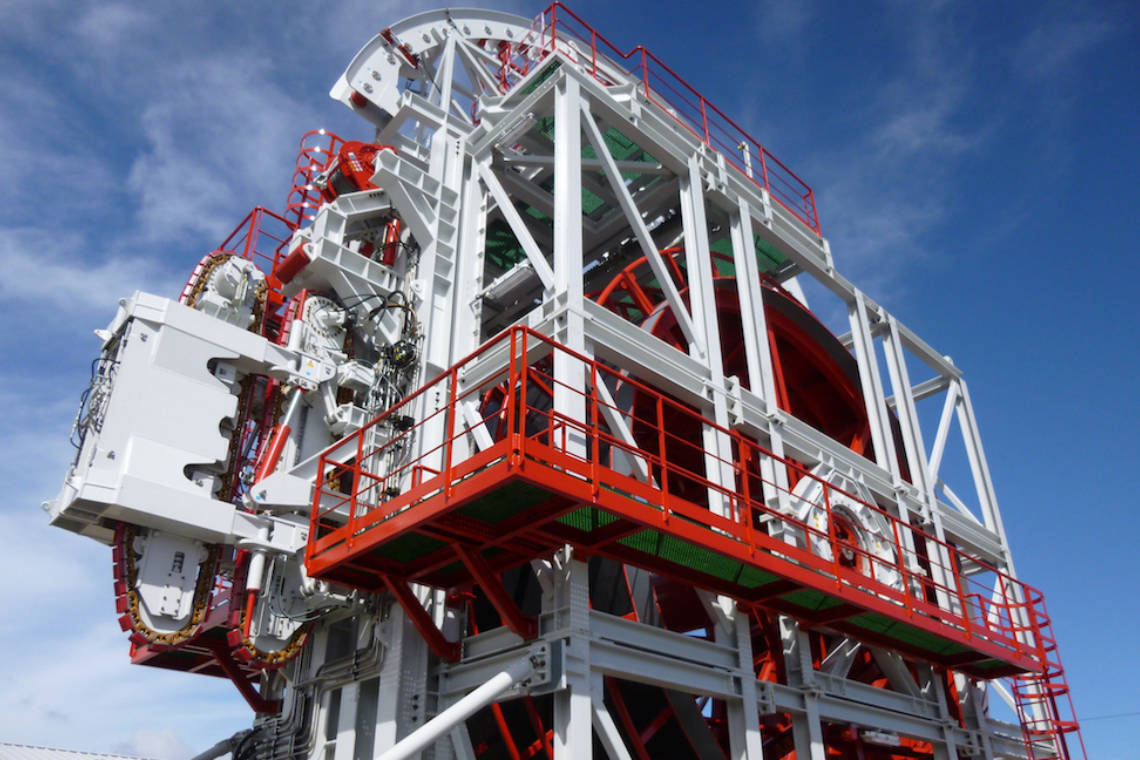

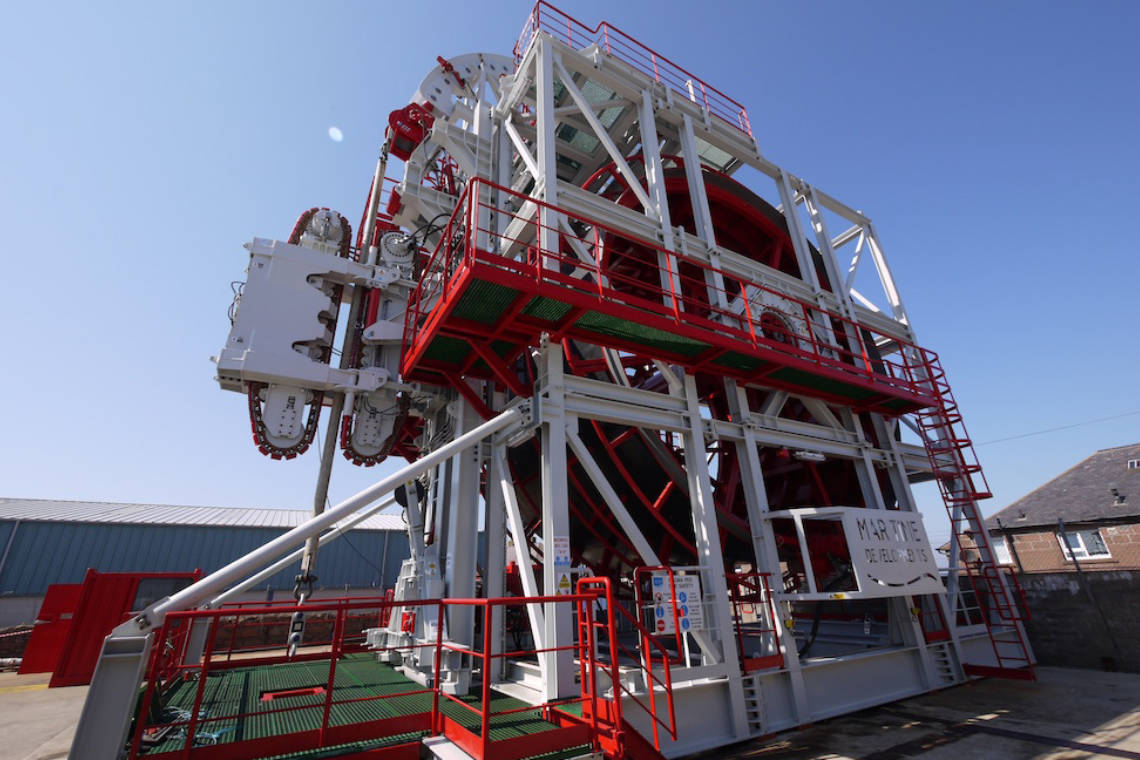

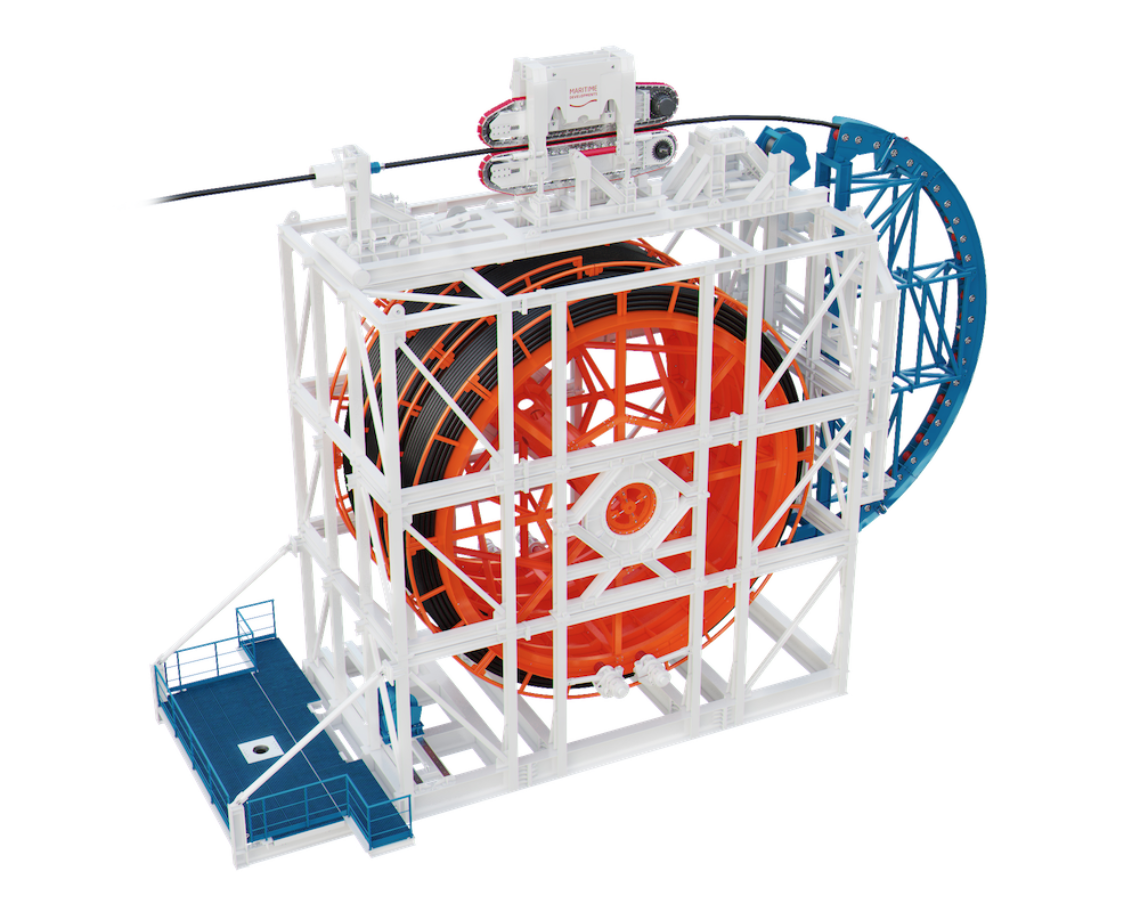

4.1MBR Product Deployment System

The PDS is a compact product deployment system for the deployment, retrieval and storage of subsea umbilicals, risers and flowlines (SURF) or composite pipe.

Operational Specification

Lay spread type

Vertical or horizontal

Tensioner operational mode

2 track mode

Track contact length

2.44m

Properties

Dimensions

14.5m x 8.5m x 16.4m (LxBxH)

Weight

150Te (empty)

Reel diameter

8.2m/9.5m (core/OD)

Weight - 30Te (empty)

Movable top chute

±13º

Work platform deck area

20m2

Work platform deck capacity

1Te/m2

Work platform opening

1.5m

Product Handling Requirements

Low tension MBR

4.1m

Maximum pipe length

3200m (3inch composite)

Maximum grip

86Te/track

Maximum squeeze

35.3Tem/track

Product speed

Variable to 1200m/hr (at 60Hz supply)

Minimum reel torque

2.1Tem

Component Parts

Integrated hang-off clamp

Integrated 5Te pull-through winch with sheave

Integrated 25Te deployment winch above tensioner

Ancillary Equipment

Electro-hydraulic powerpack

5.0m x 2.6m x 2.5m (LxBxH)

Weight - 12Te

Control van

3.0m x 2.4m x 2.5m (LxBxH)

Weight - 4Te

Spares container

3.0m x 2.4m x 2.5m (LxBxH)

Weight - 6Te

Design Appraisal

Design appraised in accordance with DNV standards

Lifting Equipment

All items supplied with dedicated rigging rated for offshore lifts

Assumed Conditions

Humidity

Up to 100%

Atmosphere

Marine/high salinity

Hose & Cable Package

20m set from HPU to reeler

20m control cable from control van to HPU

Wireless Walk About Box supplied as option for control

Power Requirements

Supply 1 (main system)

2x 132kW

3 Phase, 440V, 60Hz, 400amp supply at full load

Additional Information

The integrated system consists of a tensioner system mounted on a frame with an enclosed 9.3m diameter reel and a movable entry/departure chute.

The reel is fixed within the unit’s frame and does not require separate sea fastening onto deck.

The unit can deploy or retrieve the product both in vertical or horizontal orientation, guided by the pivoting top chute.

The tensioner’s top track is mounted on kingpins so it can pivot to open or close as required by the operator through two hydraulic cylinders.

The tensioner’s bottom track is fixed onto the reeler frame with load cell pins to allow accurate load monitoring.

During operation both the top and bottom tracks are synchronised to deliver the same amount of torque from their respective electric motors.

The unit is supplied with a dedicated electro-hydraulic powerpack.

These specifications apply to a 3inch 15kpsi pipe at 3200m length. System specifications for other pipe length, diameter and design pressure will differ.