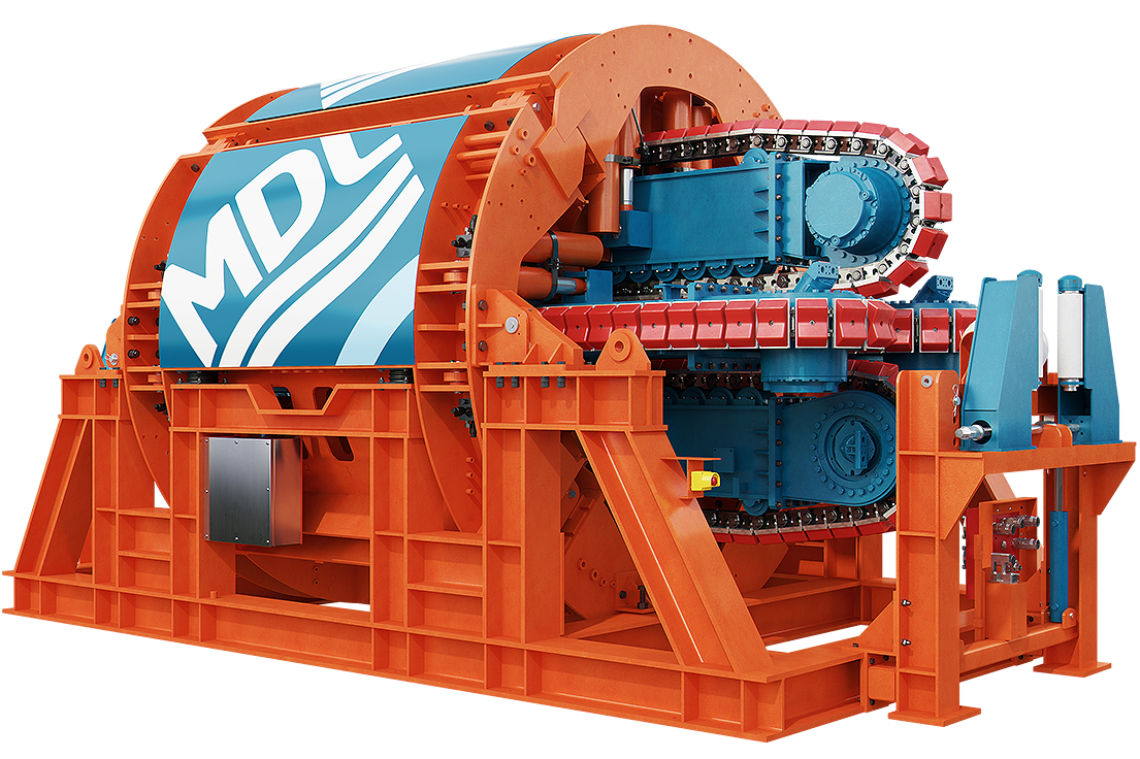

TTS-4/180 Series Tensioner

4-track system

The MDL TTS-4/180 Series Tensioner is a 51Te – 4-track caterpillar track system for the installation or recovery of flexibles, cables, umbilicals and steel pipe products.

The caterpillar tracks are fitted with ‘V’ shaped pads and operate by gripping the product between the opposing track carriages with failsafe hydraulic cylinders.

Properties

Tensioner

6.15m x 3.5m x 3.55m (LxBxH) - without containment rollers

7.37m x 3.5m x 3.55m (LxBxH) - with containment rollers

Weight (assembled) - 46.9Te without containment rollers, depending on pad configuration

Specification

Operational mode

2 or 4 track mode

Max pull force (idler end)

51Te at 0.07 CoF (4 track mode)

25.5Te at 0.07 CoF (2 track mode)

Product speed

Variable to 900m/hr (at 60Hz) – provided digitally

Tension control

10 – 100% – provided digitally

Product range

50 – 600mm OD (to cover range additional pad sets required)

Track contact length

4.074m

Maximum grip

728Te (4 x 182Te) – provided digitally

Max squeeze/m

44.7Te/m/track

Maximum track opening

800mm (without pads)

Ancillary Equipment

Electro-hydraulic powerpack

5.0m x 2.3m x 2.4m (LxBxH)

Weight – 12Te

Control van

3.0m x 2.4m x 2.5m (LxBxH)

Weight – 4.0Te

Spares container

3.0m x 2.4m x 2.5m (LxBxH)

Weight – 6.0Te

Spreader beam

6.26m x 0.25m x 0.56m (LxBxH)

Hose & Cable Package

20m set from powerpack to tensioner unit

20m power cable from powerpack to control van

20m power cable from powerpack to vessel

Lifting Equipment

1 x lifting rigging set for the tensioner

1 x lifting rigging set for all ancillary equipment

Assumed Conditions

Humidity

Up to 100%

Atmosphere

Marine/high salinity

Power Requirements

Supply 1 (main system)

3 Phase, 440V, 60Hz, 400amp supply at full load

Additional Information

The unit is designed for mounting horizontally on a deck, inclined on a ramp or hung off vertically.

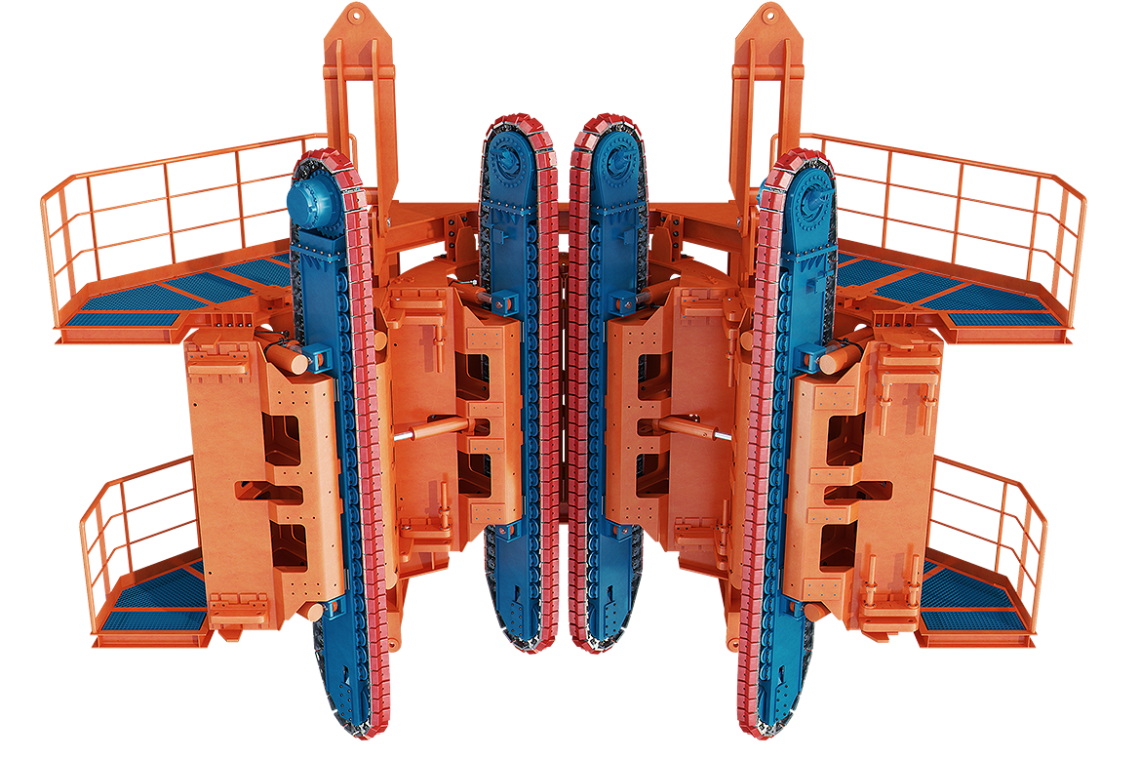

The tracks are driven by hydraulic motor/brake/gearbox drive assemblies to deploy or retrieve product.

All four track carriages are mounted on the main circular structure which is attached to either the base frame, or a vertical lay system through load cell pins which provide accurate product load information.

In the horizontal or inclined lay mode one track opens to load/unload product.

In the vertical lay mode two tracks open to load/unload product.

The unit is supplied with a dedicated dual electro-hydraulic powerpack.

Custom track pads can be supplied to suit various products.

Operates in 2 or 4 track mode.

Road transportable or can be shipped by container in component form.

Supplied with quick connect/disconnect hoses.

An electric drive option with EPU is available for purchase.

Facility for data logging can be supplied.