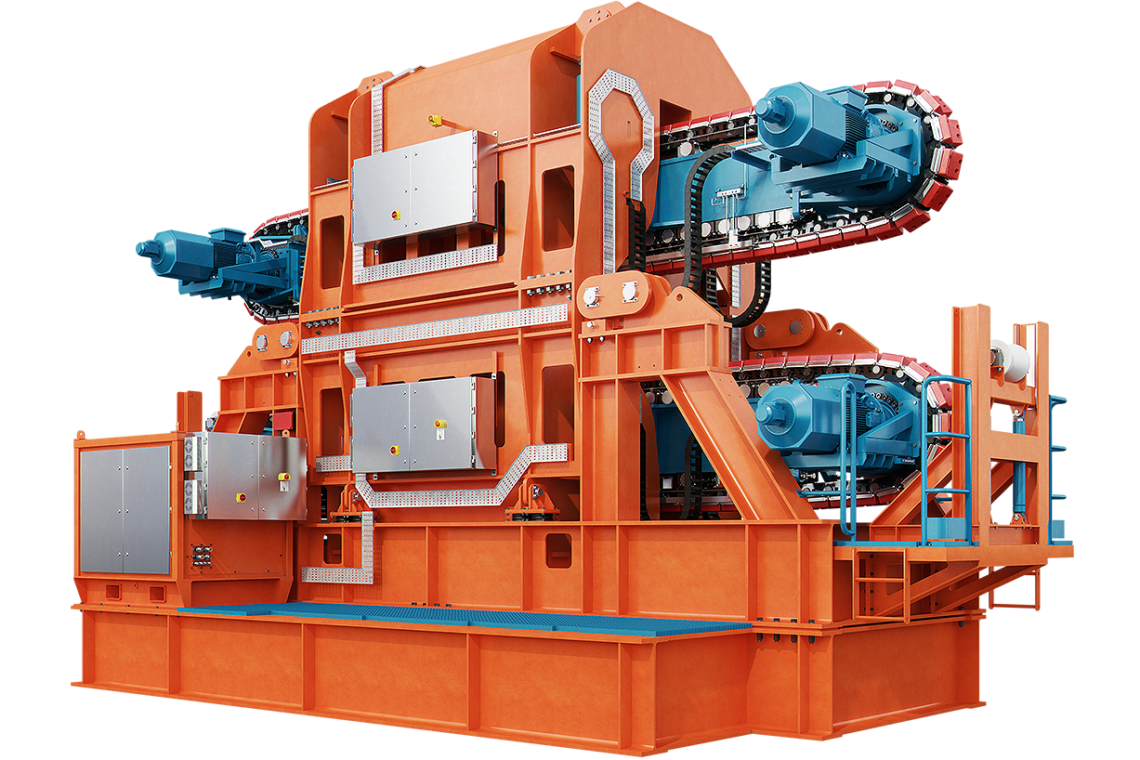

TTS-2/750 Series Tensioner

2-track system

The MDL TTS-2/750 Series Tensioner is a 150Te line pull, 2-track system for the installation or recovery of flexibles, cables, umbilicals and steel pipe products.

The tracks are fitted with ‘V’ shaped pads and operate by gripping the product between the opposing track carriages with failsafe hydraulic cylinders.

Properties

Tensioner

10m x 5.7m x 5.4m (LxBxH) assembled 97Te

Specification

Operational mode

2 track mode

Track contact length

6.12m

Nominal squeeze

1500Te (4 x 375Te)

Nominal squeeze/m

123Te/m

Maximum operational line load (both directions)

150Te at 0.1 CoF

Product speed (both directions)

Variable to 600m/hr (at 50Hz supply)

Tension control

10 – 100%

Product Capacity

Product range

75 – 630mm OD (wider range covered by additional track pad sets)

Maximum pad opening

900mm

Firing line centre height

2m and above

Firing line adjustment

0 - 200mm

Ancillary Equipment

EPU with control station

6.0m x 3.0m x 2.8m (LxBxH)

Weight - 13Te

Lifting Equipment

1 x lifting rigging set for the tensioner

1 x lifting rigging set for all ancillary equipment

Hose & Cable Package

20m set from HPU to tensioner unit

20m power cable from EPU/control van to tensioner unit

20m power cable from EPU/control van to vessel

Design Appraisal

Humidity

Up to 100%

Atmosphere

Marine/high salinity

Power Requirements

Supply 1 (main system)

3 Phase, 400V, 50Hz, 630amp supply at full load to suit onshore supply

Additional Information

The system can deploy and retrieve pipe at the same operational line load and speed.

Variable speed and tension control in both directions.

Tracks are driven by electric drive assembly to deploy or retrieve the product.

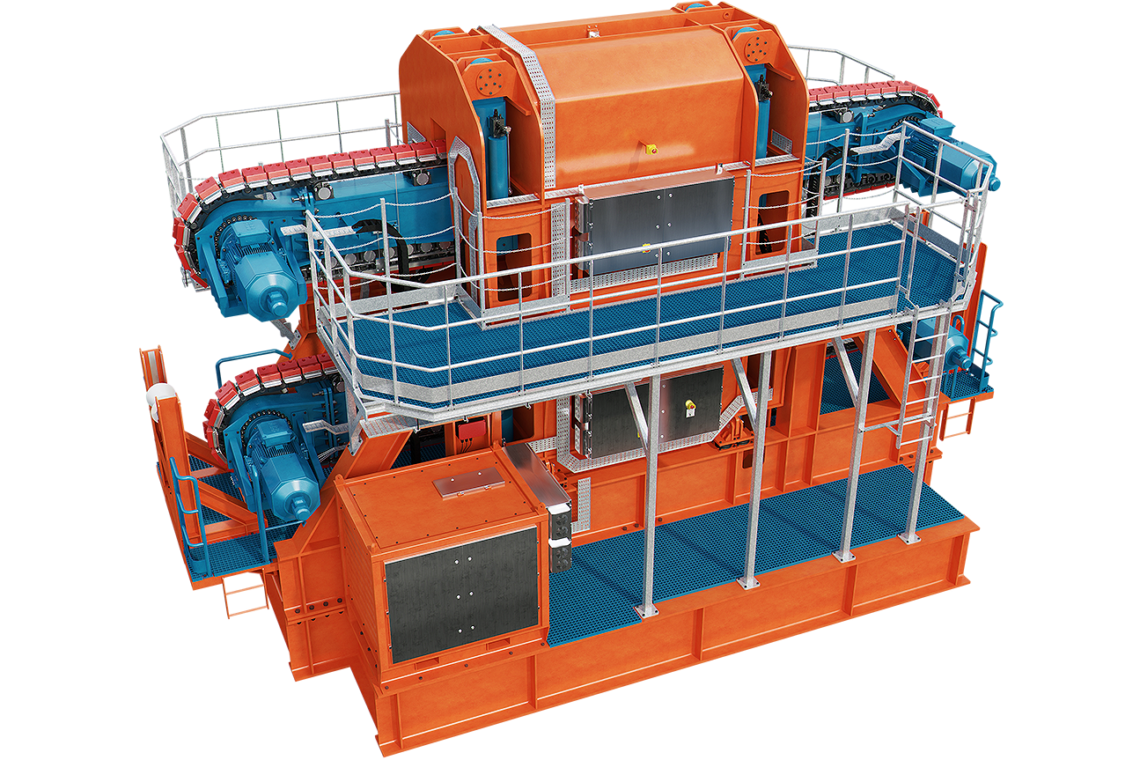

The two track carriages are mounted in the main structural frame. This is connected to the mounting frame with low shear mounts and load cell pins for accurate product load information.

Both tracks open hydraulically to load/unload product and close to grip the product when operational.

Both tracks can also move vertically to allow adjustment of the firing line by 0-200mm.

For Pipe-in-Pipe applications, the tensioner features a simple foundation frame, designed to interface with frame buried into concrete on site for ease of installation and maintenance.

Operation and safety systems can be integrated with the full production line with separate safety stations linked in to provide safe, defined and interlocked production steps.

A HPU is integrated in the tensioner base frame, which drives the squeeze system, track adjustment and support rollers.

Supplied with a dedicated EPU with control desk integrated into a partitioned 20ft container.

Features remote access for 24/7 MDL support with fault diagnostics and troubleshooting.

Adjustable support rollers at exit and entry of tensioner.

Standard and custom track pads can be supplied.

Unit features a compact footprint and is road-transportable.