Unlocking West Africa's potential

MDL BD & Commercial Manager Dave Gardiner explores why the company's portable pipelay spread is just the thing West Africa requires.

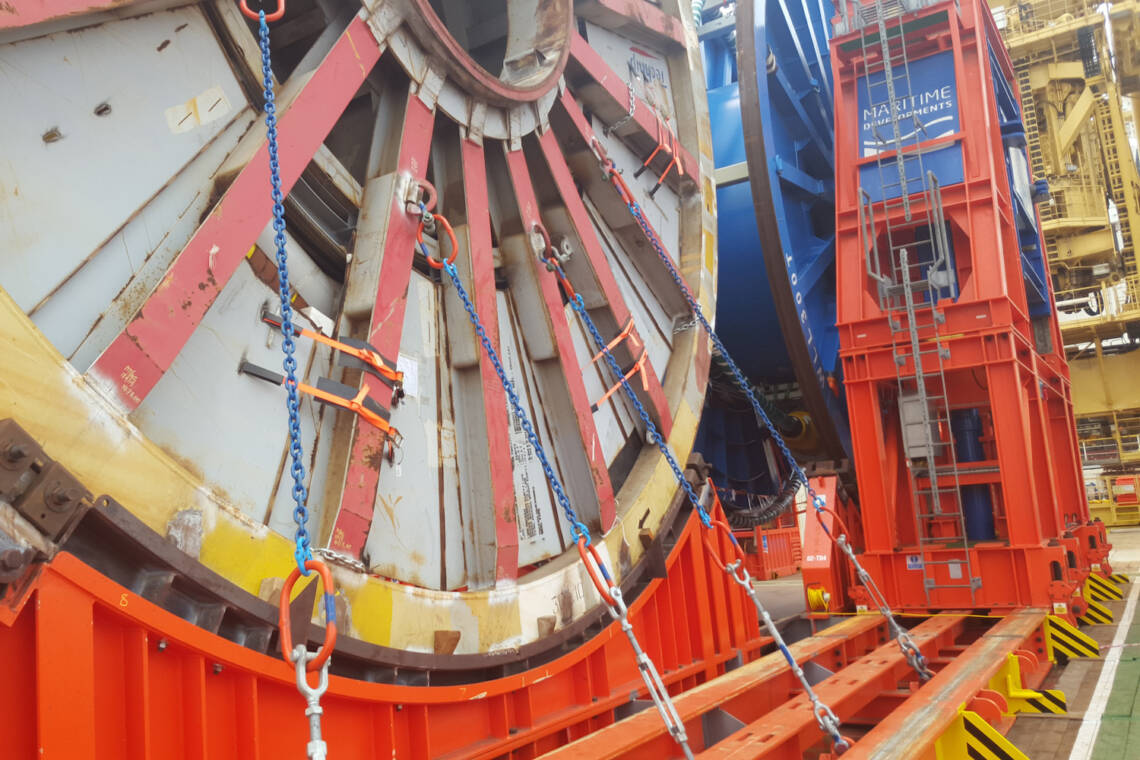

In April, MDL completed a work scope in the EN-09 field, part of Ghana’s major TEN development. The project consisted of an installation of a flowline using MDL’s Third-generation Reel Drive System.

This system made its international debut in West Africa in 2016, working for Marine Platforms Ltd. in the Agbami field. Similar to 2016, a driving factor for the RDS selection was its narrow footprint and fully-integrated design, which made mobilisation/demobilisation of the system and reels much more efficient and safer for all parties involved.

What makes MDL particularly attractive to West Africa? The technology is the first obvious answer, as the example of our Third-generation RDS has shown.

Thanks to its portable design, compact footprint and complete integration, the MDL flexlay equipment fleet is ideal for short or difficult-to-schedule pipelay projects. A complete spread can be assembled on the quayside prior to vessel arrival, then lifted on board and fully sea-fastened quicker than any alternative equipment of similar size.

Automation of systems and remote controls allow for more efficient mobilisation and operation, allowing the personnel to stand in the most optimum position on deck, while keeping them safe.

Naturally, building these systems, maintaining them after every job and performing regular software upgrades requires a dedicated time and resource commitment from MDL, for every piece of kit. However, this investment that MDL makes as a company results in time and cost savings for the end client, on every single project.

MDL’s market-leading technology stemmed from our heritage of growing up in the North Sea. This challenging, ageing basin is a great test of character for operators and contractors looking to make a profit on their E&P in this part of the world - and even more so for the supply chain who work hard to provide them with the best tools to do so.

These challenges can range from: limited access to specialist pipelay vessels, schedule clashes, weather challenges, and of course, tight budgets magnifying the negative effects of all of the above. That is why MDL focused its R&D on equipment that is easy to transport, easy to mobilise, highly automated and safe to operate.

Next in MDL’s journey of development we set our sights on the Americas and the Gulf of Mexico, where some of the above challenges were more pronounced, but the supply chain to address them was less developed.

MDL turned its focus to making deepwater operations more achievable with fewer assets - by definition, making them more economical. That is how our 85- to 150-tonne road-transportable pipelay tensioners came to life.

This unique fleet’s track record includes installation of umbilicals in over 1350m water depth and performing beach pulls - without the burden of a large installation vessel, due to their significantly smaller footprint, offset with track length longer than the market norm. In fact, one of the recent projects of our 150Te tensioner was to install oil offloading lines in over 1670m water depth offshore Nigeria…

Today, MDL is bringing our collective knowledge and experience of addressing global pipelay challenges to West Africa, where we intend for it to stay.

Our third-generation RDS remains in country booked for its third West Africa mission due to commence imminently. Upon completion, the RDS will remain in region ready to take on any challenge.

MDL is open to working with other contractors and operators across West Africa to identify what services and equipment would truly improve their operations - so that our investment in the region can benefit the local industry for years to come.

Dave Gardiner, BD & Commercial Manager

- April 2024MDL supports Saipem on Greece INGS

- January 2024Preparation is key to a long life subsea

- January 2024Forward thinking with Holland

- January 2024Ensuring peak performance for FPSO and platform owners in 2024

- December 2023Reducing the risk of cable failures