It all adds up for single-sourcing

Planning a wedding is no small matter... neither is planning for a pipelay project. MDL's Senior Structural Engineer Steven Ross delves into both.

Wedding planning is a very exciting and creative phase of your life. Through collaboration, you organise a large range of suppliers to buy in to delivering your vision, to make your wedding day the best day of your life - a process I have the joy of undertaking at present.

Wedding planning is a significant undertaking, with a large range of suppliers to identify, vet, negotiate, book and manage. This is an enjoyable process, but is demanding mentally and is very time consuming, which has made me reflect: would it not have been easier to employ a professional Wedding Planner? They could have streamlined the process and delivered our dream day as we envisioned it, giving me more time to get beach-ready and conclude my speeches.

The Wedding Planner would be able to manage all the logistics of the day by employing trusted suppliers, managing contract negotiations, manage the delivery, the schedule, and being our one point of contact throughout. Would this not have been so simple - to deal with one expert, who knows the venue better than anyone and knows the whole wedding process inside out?

Comparing that to my work life, I can see the benefits of single-sourcing.

Coming from a back ground of extensive vessel integration design works, I know the laborious process of;

- Data gathering from all equipment suppliers, including AutoCADs, equipment fastening points, equipment design criteria and equipment capacities, and the challenges of reluctance of data sharing with subcontractors;

- Working with the vessel team, client, end client, full range of equipment suppliers, engineers and offshore team, and consultancy project engineers, to try to make the deck work for all;

- Liaising through the client to support any Class Approval queries;

- Vetting a range of fabricators, rigging suppliers, haulage firms, and organising Class on-site surveyors.

All of this without the (common) occurrence of a potential equipment change-out at the last-minute, requiring re-positioning, draughting and engineering… This drawn-out process is a lot of work, and creates many suppliers for the client to source, manage and reimburse; however, there is another option - the “Wedding Planner” route.

At MDL we hit the ground running when it comes to deck planning and sea-fastening design. Since we engineer and manufacture our own equipment, we possess:

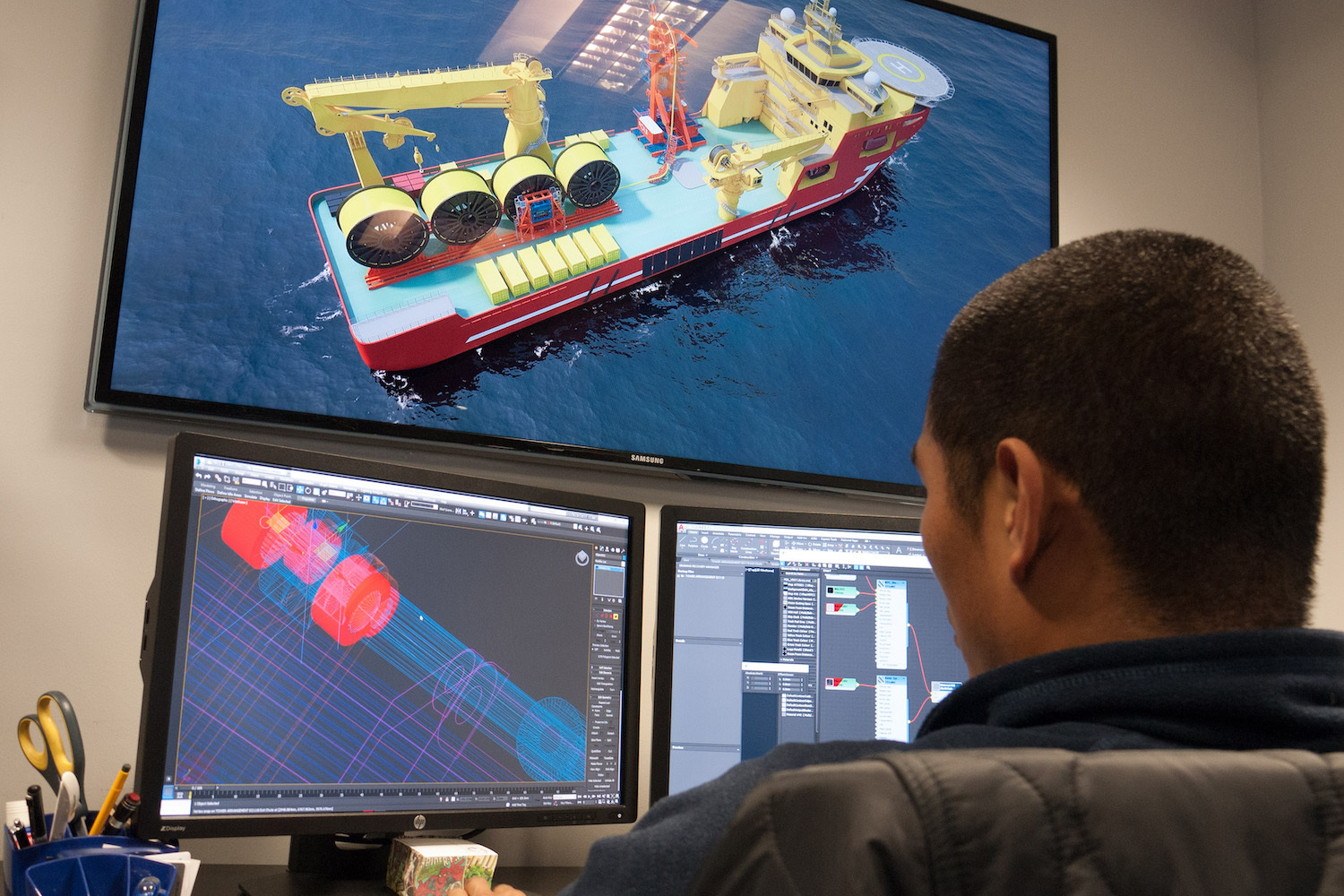

- A full-time graphic designer with a significant range of DSV vessels and all MDL equipment modelled;

- AutoCAD Inventor Assemblies and 2D AutoCAD of all MDL equipment, including standardised “clash free” fastening for all equipment;

- The DNV GL-approved design calculation packs, so we know exactly the equipment design criteria, allowing us to support the client to make the most out of all systems, instead of offering just a blanket system rating;

- Designated project team who provide clients pre-, during and post-project support for MDL equipment integration on vessels across 100s of offshore campaigns;

- Offshore technicians who have 1000s of hours of experience of integrating and operating the equipment in the offshore environment.

I always say that for equipment integration engineering, it is split roughly in half between understanding the equipment and understanding the vessel; however, you have already eliminated 50% of the work by using MDL equipment and the MDL engineering team. In addition, if the vessel is one we have worked on before, that simplifies the process even more, making the MDL offering a very lean proposition against others in the market - which is usually not the case when it comes to single-sourcing.

MDL have managed the fabrication and delivery of all our equipment, additionally FAT-tested all the equipment on the MDL Peterhead test bed, therefore the single-source offering from MDL includes:

- Full deck plans 2D and 3D;

- Engineering and fabrication drawings;

- Class Approval management, providing stamped approved sea-fastening drawings;

- Equipment Match drilling, modification, trial gusset fit up and FAT testing;

- Equipment delivery on-site complete with: fabrication requirements; rigging and lashing requirements; gusset plate cutting; Senior Structural Engineer to ensure smooth vessel integration and Class approval; Offshore Technicians to set up and operate the equipment.

The offering creates a very attractive and fully-encompassing package for the market - a one-stop shop for all your back-deck needs.

It’s not just the time and cost savings single-sourcing can offer, but rather the knowledge that it can bring into the process. MDL can effectively optimise the deck for the complete work scope - making the vessel work for you, not the other way around.

Our design team is experienced in preparing story boards and deck layouts for clients who know exactly what they want, but also have the expertise to visualise options when an innovative solution is required. This is not limited to MDL equipment. We have some of the most creative people I have worked with, as the concept designs for a huge variety of back-deck solutions I have collaborated with since I began is superb and produced in crystal-clear renders, thus basically providing as part of a formal tender a free concept design phase, which sets MDL apart from your typical consultancy.

Because we incorporate project management into our manufacturing and flexlay soloutions processes, we are well organised to assist clients with initial tender support, providing outline schedules, equipment/engineering costings and initial deck plans. MDL can provide vessel integration design for any market operation equipment or subsea structures, and through my extensive involvement in vessel integration for the decommissioning market, that is certainly something MDL have the expertise to provide solutions for.

So, by this point we’ve streamlined services from a range of suppliers into one complete package – yes, that means one point of contact and one weekly progress meeting making a client’s (and a bride and grooms’) life significantly easier.

Ultimately, whether you’re employing multiple suppliers or single-sourcing, the result should be the same: a fully functional back deck design, optimised for your project. However, a single supplier is the straightforward route to improving project efficiency, by offering a single focal point, streamlined communication, documentation, and project support right through to completion.

Personally, I’ve done my wedding planning the hard way (albeit my Fiancé has done the majority of the planning), but managing 20 suppliers is a real challenge. Thankfully, I just have to do it once.

Steven Ross, Senior Structural Engineer

- April 2024MDL supports Saipem on Greece INGS

- January 2024Preparation is key to a long life subsea

- January 2024Forward thinking with Holland

- January 2024Ensuring peak performance for FPSO and platform owners in 2024

- December 2023Reducing the risk of cable failures